Digital Engineering Takes a Big Step Forward in 2021

Last year Zuken predicted that 2020 would kick off a decade of digital transformation. And we still stand by that prediction in 2021. 2021 will see significant forward progress on the digital transformation journey, particularly in the related space of digital engineering.

Let’s take a step back and discuss what we mean by the digital transformation, looking at it from the perspective of electrical/electronic product development. I think we would all agree that products are becoming more sophisticated through advanced electronics. Processors and sensors are more powerful to enable the software to do more things for us. These advances represent human convenience, from your autonomous driving assistance to your smart vacuum cleaner. As more and more of these feature-rich smart devices become part of our lives, we become more exposed to the potentially severe consequences of poor design when things go wrong.

Digital transformation and, more specifically, digital engineering, introduce a shift in methodology from a document-based design process to a model-based design process. A process that can help engineers avoid the pitfalls and consequences of poor design. A model-based design process shifts the critical steps from design, build, test, to design, analyze, build. The model versus document approach provides a much more rigorous product description, including safety protocols and environmental requirements.

But what steps will we see in 2021 that will move the Digital Engineering ball forward?

Prediction: The First MBSE to Wire Harness Design Process

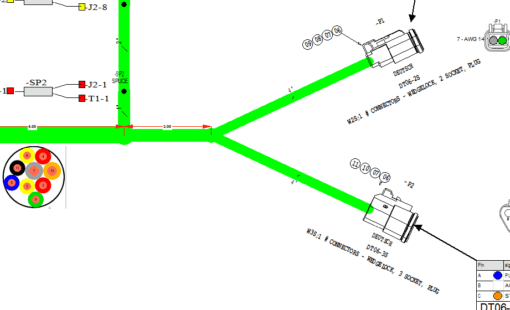

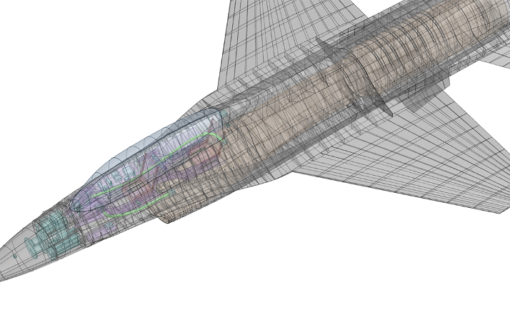

Model-Based Systems Engineering (MBSE) has a strong foothold in the Mil/Aero industries based on the DoD’s Digital Engineering Strategy published in 2018. But in many cases, the model requires manual translation to documents–often taking weeks before the start of the implementation process. The biggest documentation challenge is the interconnect, or interfaces, between the electronic control units implemented as wire harnesses.

One of the foundational elements of a digital engineering process is the adoption of a model-centric design process, eliminating outdated, inefficient document-based processes. With the acquisition of Vitech Corporation in 2019, Zuken now has all of the critical elements to provide a model-based design process.

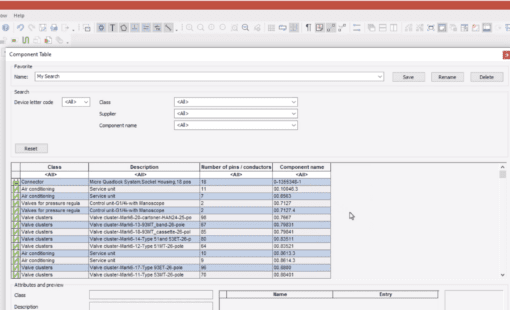

Now consider this, what if you could connect a digital model to a wire harness design tool without the need for manual translation–a direct connection. More specifically, a wire harness model created in GENESYS could be directly transferred to E3.series for implementation. The model would suddenly become part of the product life cycle and have a significant impact on ROI. Because the model is a more rigorous definition of the product than can be constructed using documents, more information is conveyed directly to the design and test teams. Inconsistencies with the model will be quickly detected in terms of design parameters (e.g., weight allocations), requirements, functionality, and safety. The result is a high-quality product consistent with the design intent. The ROI benefit will include time to market, lower cost, and most importantly, a higher quality product.

The model-based PCB design process will soon follow. Offering an electrical and electronic model-based design process with a direct connection to detailed design makes the model-based design paradigm more attractive to the entire electronics market.

2021 could be an exciting year for model-based design . . .

Related Products and Resources

- Blog

- Blog

- Webinar

This webinar will discuss the relationship between systems engineering, digital engineering, and MBSE in creating the framework we need to deliver complex products.

- White Paper

This eBook describes an MBSE based process for Electrical and Electronic design. The eBook begins with model content and structure with the purpose of implementation and the need for a “design envelope”.