Transform Control Panel Assembly with Easy-to-Follow Digital Wiring Instructions

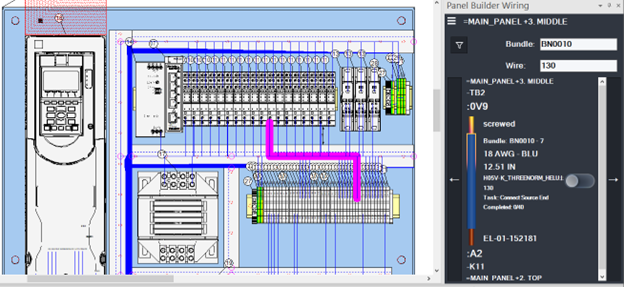

Precision and efficiency are crucial for success in electrical panel and enclosure manufacturing. Zuken’s Wiring Task Manager (WTM), a function of the Panel Builder for E3.series plugin, emerges as a transformative tool for the industry. Designed to guide technicians through the wire installation process, WTM ensures accuracy and boosts productivity. Here’s a closer look at how WTM can revolutionize your manufacturing process.

Understanding E3.series and Wiring Task Manager

E3.series is a comprehensive ECAD solution tailored for electrical design, offering advanced capabilities in 2D and 3D control cabinet design. With E3.panel, engineers can create detailed layouts in both 2D and 3D, facilitating a seamless design-to-manufacturing workflow. It features automatic design rule checks, catching errors early in the design process.

WTM builds on this robust foundation by offering a step-by-step guide for wire installation. This integration bridges the gap between design and execution, transforming complex wiring tasks into streamlined processes.

Guided Wiring Installation

The main feature of WTM is its ability to provide precise, step-by-step installation guidance for each wire in a panel while tracking each task’s completion status. This functionality eliminates guesswork, ensuring that technicians know exactly where to connect each wire, the path the wire should take, which terminals to crimp, and the precise length of wire required for each connection. Additionally, WTM intelligently orders installation tasks in an efficient manner to reduce technician movement.

Another key benefit of WTM is its ability to reduce training time for new technicians. The clear, step-by-step instructions help novices understand complex wiring tasks, allowing them to become proficient more quickly. This reduces the training burden on experienced staff and ensures all team members can perform wiring tasks to the same high standard.

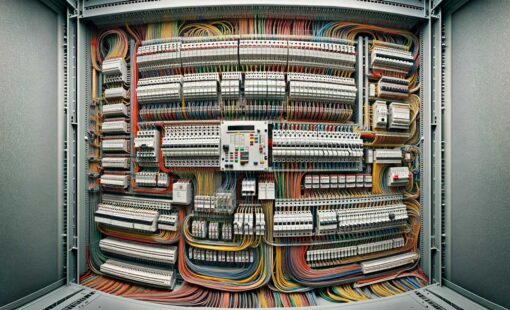

Imagine a scenario where a technician faces a complex control panel with hundreds of wires they must install correctly. Using WTM’s guidance, the technician can follow clear, easy-to-understand instructions, making the process much more manageable and efficient while tracking the completion status at a wire-end level. This speeds up the installation process and improves the overall quality of the work, leading to more reliable end products.

Integration with E3.series

The seamless integration of WTM with E3.series ensures that wiring tasks are consistent with the original design data. This integration is crucial for maintaining design integrity, ensuring the physical installation perfectly matches the schematic. By utilizing the design data from E3.series, WTM provides a comprehensive wiring plan that aligns with the design specifications, reducing the risk of discrepancies and ensuring a smooth transition from design to production.

For instance, if a design change is made in E3.series while the design is already in manufacturing, the engineer can push those changes to WTM. In doing so, not only are installation tasks added for any new wires, but uninstall tasks are created for any wires that were already marked as installed but are no longer in the project. Doing this using paper drawings or PDFs would be extremely time-consuming, but using WTM ensures that the wiring installation remains accurate and current with no manual comparison efforts. This dynamic integration supports a digital thread throughout the manufacturing process, enhancing overall workflow efficiency and reducing the risk of costly errors.

Streamlined Workflow Between Design and Manufacturing

One of Wiring Task Manager’s significant advantages is its integration with Komax and Schleuniger wire processing machines. By generating outputs that are directly compatible with these machines, WTM ensures a seamless transition from digital design to automated manufacturing. This integration not only accelerates the wire processing stage but also enhances the accuracy and consistency of wire manufacturing while reducing manual labor and the potential for human error.

Wire processing automation increases production speed and output, allowing manufacturers to effectively meet tight deadlines and scale operations while reducing the waste associated with manual wire length cutting and bad crimps. These machines are capable of precise execution of wire cuts and crimps, ensuring high-quality, reliable products and minimizing rework and waste. This makes WTM an asset for companies aiming to enhance their production capabilities and maintain competitive advantage.

Financial Benefits

From a financial perspective, WTM helps companies save on labor and material costs by manufacturing wires exactly as needed, minimizing errors, and reducing rework. The improved efficiency and quality also lead to better customer satisfaction, resulting in fewer warranty claims and increased repeat business. Additionally, the seamless integration with E3.series ensures that the transition from design to production is smooth and error-free, supporting a digital thread throughout the manufacturing process.

Integrate Digital Wire Instructions to Enhance your Process

Zuken’s Wiring Task Manager is a powerful addition to the E3.series ECAD suite, offering unprecedented guidance and accuracy in wire installation. By seamlessly driving wire manufacturing and installation with E3.series’s electrical design data, WTM enhances productivity, improves quality, and reduces waste lowering overall costs. For companies looking to stay ahead in the competitive field of electrical panel manufacturing, WTM is an indispensable tool.

Explore how WTM can transform your manufacturing processes by contacting our sales team to book a demo.

Related Products and Resources

- Blog

- Blog

- Blog

- Blog