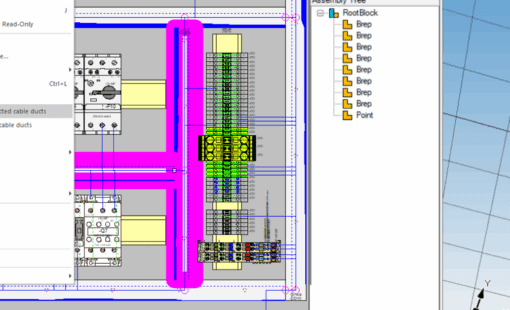

Once the design phase has been completed, and the project is ready for production, E3.series can create drill hole templates based on devices in E3.panel utilizing an Add On tool called E3.cutout. E3.cutout takes data from panel devices and generates a new E3 sheet and DXF file that the manufacturing team can use. However, there are some cases where specific devices might not need a drill hole template generated.

In this Tech Tip, I will demonstrate how to generate a drill hole template and exclude unnecessary devices.

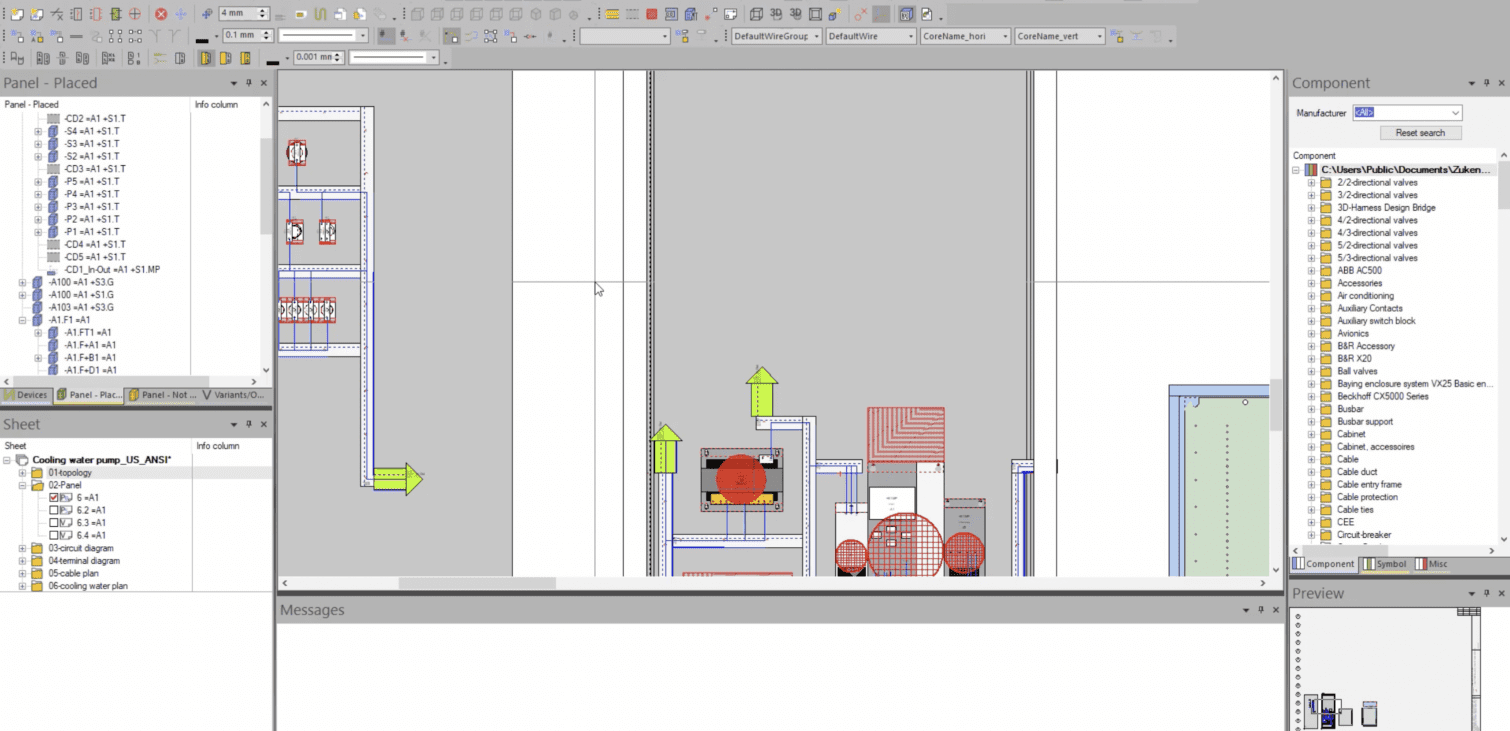

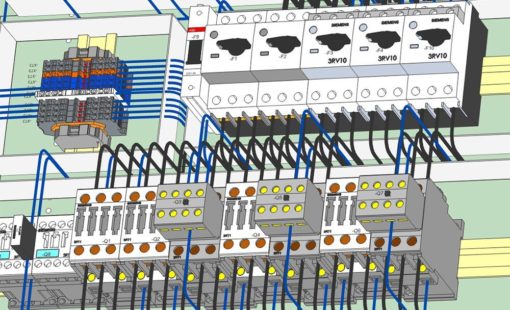

E3.panel helps identify device collisions using 3D model data during the design phase. This results in a 1:1 representation of the electrical panel, which provides proper layouts to the manufacturing team. Since the layout is already completed, generating the drill hole template is as simple as running E3.cutout. Let’s say some devices need a drill hole template developed.

The solution is to use E3.cutout and assign an attribute to the devices that do not need to be included. The first step is to assign the attribute in E3.cutout, and the second is to assign the attribute to the device. The video below will go into more detail on this topic

.

Related Products & Resources

- Products

- Products

- Products

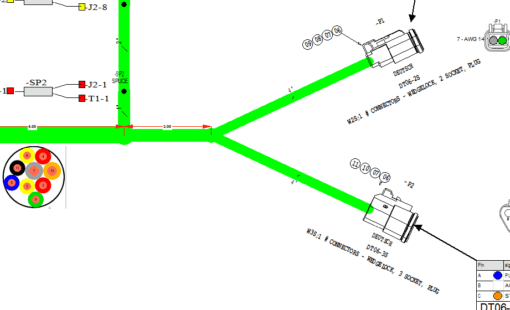

E3.series is a Windows-based, scalable, easy-to-learn system for the design of wiring and control systems, hydraulics and pneumatics. The out-of-the-box solution includes schematic (for circuit and fluid diagrams), cable (for advanced electrical and fluid design), panel (for cabinet and panel layout), and formboard (for 1:1 wiring harness manufacturing drawings). Integrated with MCAD, E3.series is a complete design engineering solution from concept through physical realization and manufacturing output.

- Blog