The Problem

Electronic components are constantly changing, causing parts to go EOL (End-of-Life) for various reasons: companies go out of business, component product lines change hands, old technology is updated with new. Electronic product manufacturers must be agile to keep their product BOMs (bill of materials) up to date and keep their supply chain humming. Fortunately for them, Zuken’s DS-CR customers leverage component and design data relationships to tackle the problem.

Three steps to mitigate EOL parts

Let’s go through the steps of identifying troublesome EOL parts, finding a replacement part, and updating the BOM to reflect the necessary changes.

Step 1: Knowledge that a part is scheduled for EOL

Before you can manage it, you need to know when a part is approaching EOL status. One approach is a parts data service such as Silicone Expert ®. Silicone Expert paired with DS-CR enables your component master to be automatically updated with part lifecycle data, including EOL status! Then it is easy to identify EOL parts that need to be replaced.

This image is a listing of parts sorted by “Estimated Years to EOL,” showing those parts that need immediate attention at the top. Click on the video below to view a brief video clip about how DS-CR is used to create such a listing.

Step 2: Identify and qualify a replacement

The first place to look for a potential replacement part is in your company’s component master. Ideally, you’ll find a suitable part already qualified and ready to use. DS-CR’s parametric search capability lets users scan the entire component master by part category, operating characteristics, compliance factors, and many other parameters to find a part that meets specific criteria.

If a component master match isn’t found, then you’ll turn to a parts search service to find your new part. Silicone Expert has excellent search features, and part properties can be imported from Silicone Expert into DS-CR to save time-consuming, error-prone manual entry. Download a datasheet, attach it to the part and submit it for processing using the New Part Request form.

DS-CR provides workflow capabilities so a new part is guided through the qualification process without missing any steps, it includes review/approval checkpoints that ensure unapproved parts aren’t included in a production BOM. Workflow status is tracked and visible in the component master and BOM views, so everyone that needs to know is informed throughout the process.

At this point, we should discuss the two common strategies for assigning manufacturer’s parts to company part numbers: One-to-one and AVL (Approved Vendor List).

As the name implies, one-to-one relates a company part number to one manufacturer’s part. Substitute parts must be defined with an “alternate” relationship. This adds complexity for parts at EOL because all BOMs with the EOL part must be updated to effect the change. Fortunately, DS-CR handles alternate relationships between parts and the BOM change process very elegantly.

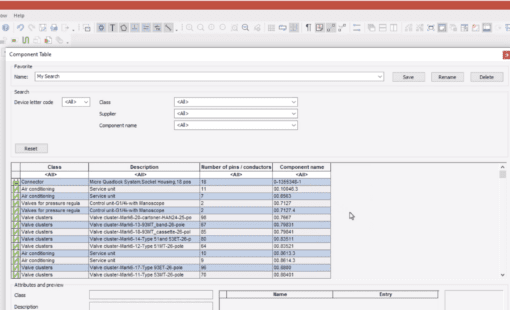

The AVL strategy allows a company part to have a list of several manufacturer’s parts that are equivalent. Each part must have the same physical dimensions and equivalent operational characteristics. A big advantage with this approach is that the manufacturer’s parts can be added and removed from the AVL to address EOL issues without having to update the BOMs containing the part. DS-CR has AVL relationships built into its data model—tracked by change management workflows—and configurable interfaces to PLM and ERP systems to sync AVL updates between systems. This image shows a company part with two manufacturers’ parts in its AVL.

The AVL strategy allows a company part to have a list of several manufacturer’s parts that are equivalent. Each part must have the same physical dimensions and equivalent operational characteristics. A big advantage with this approach is that the manufacturer’s parts can be added and removed from the AVL to address EOL issues without having to update the BOMs containing the part. DS-CR has AVL relationships built into its data model—tracked by change management workflows—and configurable interfaces to PLM and ERP systems to sync AVL updates between systems. This image shows a company part with two manufacturers’ parts in its AVL.

Step 3: Update product BOMs, PLM, and ERP systems to reflect the changes

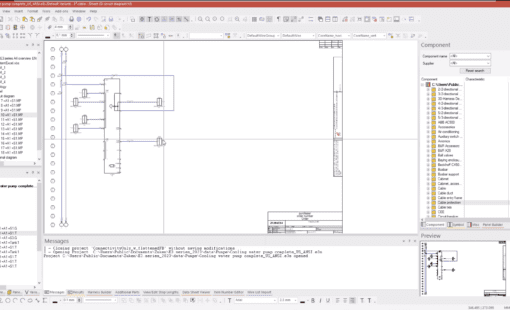

DS-CR’s CLM (Component List Manager) module is used to prepare and validate BOMs for production. It imports parts information from schematics, PCB layouts, and even CSV files. It provides full visibility to all component properties, including lifecycle status (i.e. EOL) and workflow status (i.e. approved). This information is used to ensure all parts are compliant with the company’s supply chain policies, and it highlights issues that need to be addressed before the BOM is released.

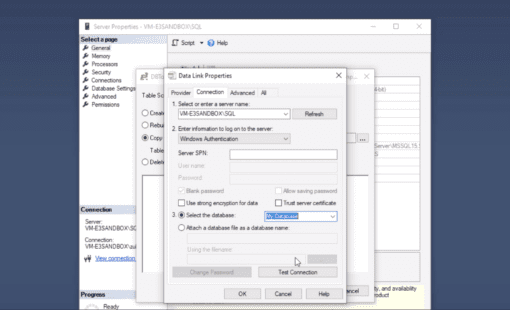

This image is a screenshot of the Component List Manager (aka BOM Manager). This tool is highly configurable to create custom views with information important to a given role. For instance, a Design Engineer and Component Engineer have different perspectives when looking at a BOM. Click on the video, below, to see how alternate parts are swapped in the Component List Manager.

Alternate part relationships defined in the component master are used to conveniently swap out EOL parts with compatible substitutes. Parametric search and replace features allow the user to make ad hoc swaps if needed. BOM changes are subject to a review and approval process using DS-CR’s change management workflows. The final BOM is retained in a vault under revision control with check-in/out features to track its history.

BOM information is used for production and supply chain planning, so it must be shared with a company’s PLM and ERP system. The previously mentioned PLM and ERP interface capability is configurable to send this information where it is needed to support production business processes.

Summary

The key takeaways are:

- Maximize use of the data available to identify EOL parts and find suitable replacements.

- Modern design automation can ease the burden of managing changes and propagating data updates needed to support business processes.

Zuken’s DS-CR platform maximizes the value of all the part and design data by linking their sometimes-complex relationships together.

Related Products and Resources

- Products

- Products

- Products

The traditional practice of mechanical, electrical and electronic engineers working in silos – then consolidating efforts late in the development process – is no longer viable for successful companies. Zuken offers a portfolio of scalable domain data management solutions for PCB and electrical/fluid design plus a range of solutions that integrate design and domain data management into the PLM and ERP world.

- Brochure