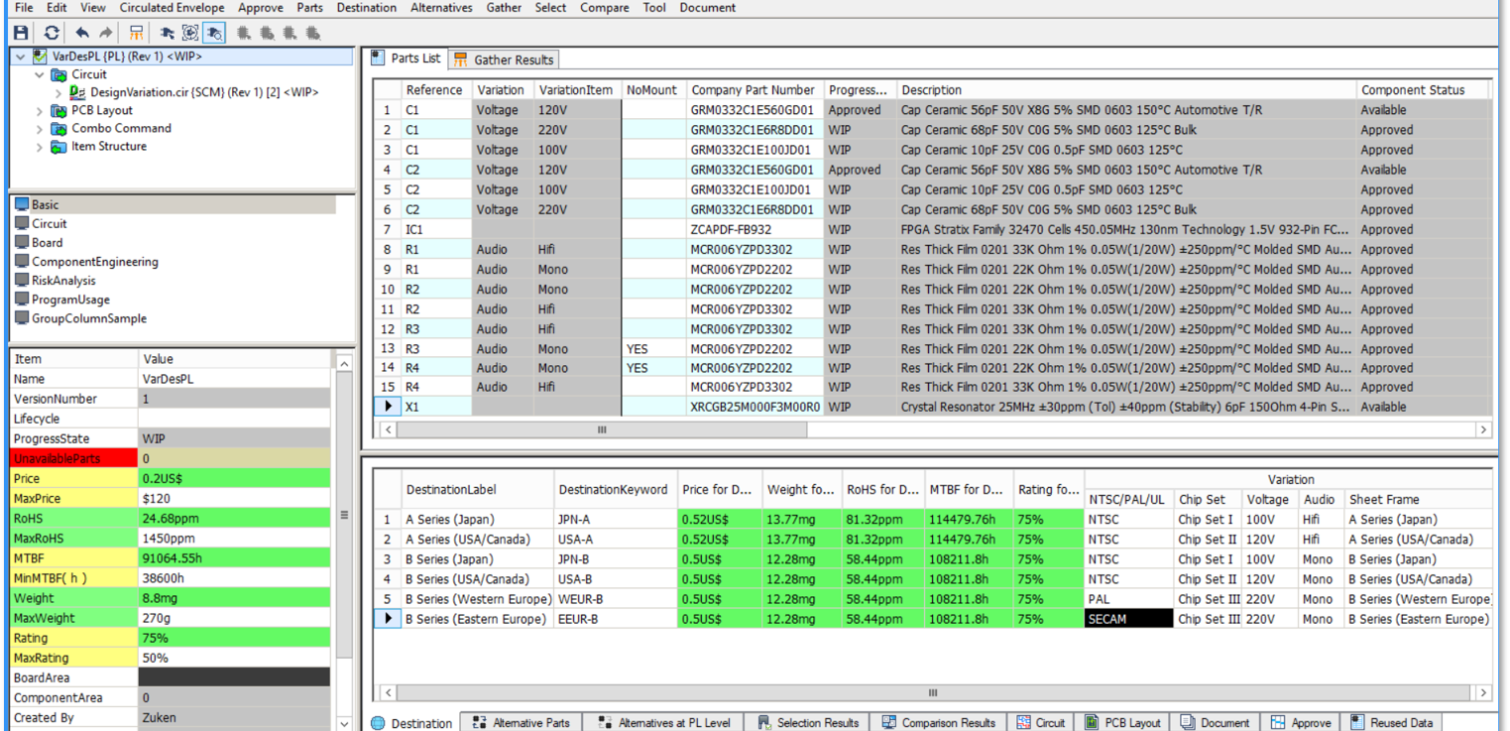

In this post, I’ll cover utilizing variants that were imported to the Component List Master (CLM) from a schematic. CLM is one of the DS-CR ePDM modules. It is used to manage component lists, often referred to as a bill of materials (BOM). These utilize data combined from the schematic and printed circuit CAD files along with data from the component database within DS-CR.

Several CAD applications are employed throughout the design process, and they all need to manage product variants. It is challenging to ensure they are all updated when design changes are made.

The following process manages variants between the schematic and parts list applications. The schematic is registered in DS-CR, and then a parts list is created and linked to it. In CLM, the parts list can be viewed and manipulated within the context of the destinations and variants that were assigned in the schematic. The user has complete flexibility to create new variants and destinations and can assign part numbers or no-mount status by variant within CLM. Any changes have reflected the schematic so both design artifacts are in sync.

The following video shows how variants are managed in CLM. In a prior Tech Tip, I went into more detail on setting up variants and destinations in CLM.

Read more of our Tech-Tips here!

- Products

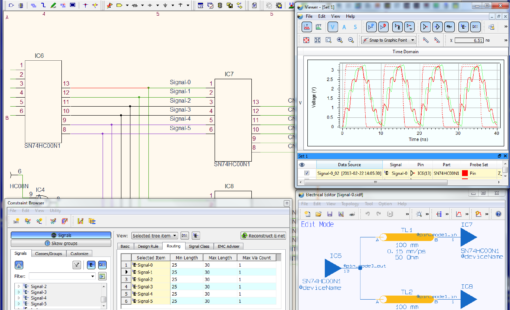

PCB Design Creation - Design Gateway is a platform for logical circuit design and verification of single and multi-board system-level electronic designs. It supports a true system-level circuit design in which individual circuits can be represented and connected as blocks.

- Products

Building a competitive product today is much more difficult than a few years ago. Existing PCB-centric design processes are limited to a single PCB and do not provide the necessary tools for today’s competitive product development environment. PCB-centric design processes are falling behind.