This is the second in my posts which talk about how electrical engineers can make a bigger impact on the product development process. Previously I focused on getting involved in the sales bidding and specification process, in part two I’m going to focus on systems engineering.

The diversity of each discipline plays a key role in the success of the project. All these elements cannot operate independently, they must be compatible and mutually supporting, and the systems engineers’ role is to ensure that this is co-ordinated.

I recently came across this bit of research by Pinto and Slevin [1] , who suggested that companies that have adopted this type of project planning and project management technique (as I describe above), experience better control and customer relations, shorter development times, lower costs, higher quality and reliability, and usually higher profit margins. Other plus points include a better focus on actual results, better interdepartmental co-ordination, and a higher working moral (now no one can snub their noses at this one).

So what about the Electrical Engineer?

We all know that in theory you can try and sell a fantastic product and even design one, but if it cannot be manufactured, tested, or made cost effectively, you’re settling yourselves up for one big fall that’s going to cost someone a LOT of money.

Although I’m sure we’ve all in some way had some experience of being sold something that isn’t real. You as the electrical engineer may feel that you can’t begin to affect the product’s success or sustainability, but nothing could be further from reality. You really can make an impact and let me tell you how…

The system level design will place you as an electrical engineer in a requirement block in the design. As I’ve already covered, every element in the product development process interacts with each other, and this will be the case here. Even inside this “electrical” block you know there can be interdependent disciplines, such as power, data, and fibre optics – and you will receive a set of requirements, not only from a customer perspective, but from a system perspective. In the early design phases, you need to think about how your design is going to be tested. How is the resulting product to be manufactured? What are the power requirements? By having your head screwed on and thinking about the design steps next in line, you are going to save your company a stash load of money.

And you’ll be thanked in a big way by your fellow work pals further down the line for taking this into account now

Next time I’m going to look at how you can make an impact at the testing stage.

Bye then.

References

[1] J.K. Pinto & D.P. Levin

“Critical factors in successful project implementation”

I.E.E.E Transactions on Engineering Management EM-34 Feb. 1987 pp 22-27.

Related Products and Resources

- Test Drive

- Products

- Products

- Products

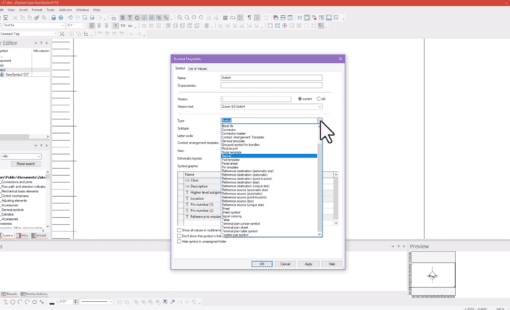

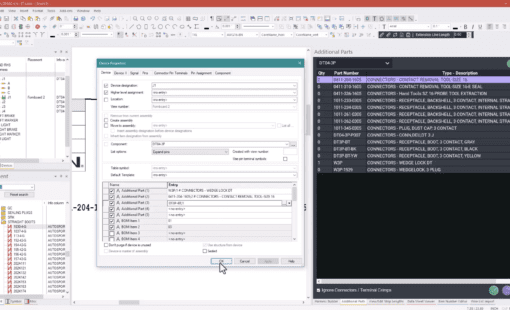

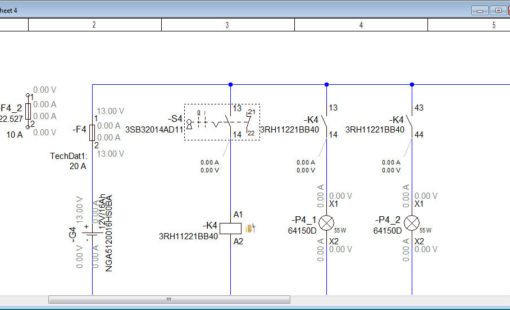

E3.series is a Windows-based, scalable, easy-to-learn system for the design of wiring and control systems, hydraulics and pneumatics. The out-of-the-box solution includes schematic (for circuit and fluid diagrams), cable (for advanced electrical and fluid design), panel (for cabinet and panel layout), and formboard (for 1:1 wiring harness manufacturing drawings). Integrated with MCAD, E3.series is a complete design engineering solution from concept through physical realization and manufacturing output.