The Significance of Visualization in Control Panel Design and Manufacturing

Visualizing designs is fundamental for electrical engineers and contract manufacturers, as it enables efficiency, accuracy, and innovation. This post explores the pivotal role of visualization of control panels and switchgear design and manufacturing, highlighting how advanced tools like E3.series transform complex electrical design concepts into understandable and actionable visual formats. Explore the impact of visualization technologies and their effect on the design and manufacturing of electrical panels.

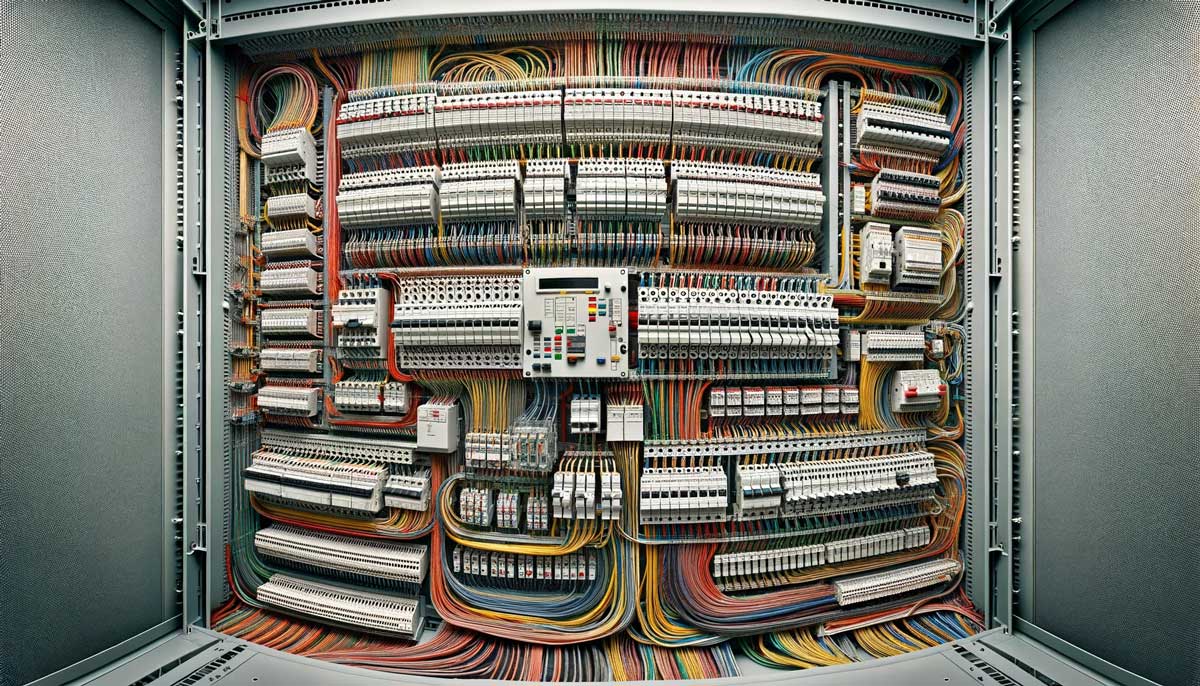

Understanding the Role of Visualization in Control Panel Design

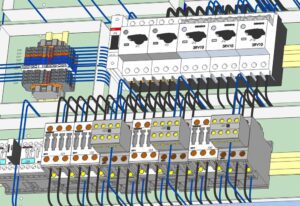

Visualization in control panel design is more than just a step in the process; it’s a cornerstone of success. It allows designers to see and understand complex wiring, component placement, and the spatial relationship within a panel. E3.series provides an immersive visualization platform, allowing engineers to create detailed, accurate, and easily interpretable designs. These visual representations are crucial in avoiding design errors and ensuring that panels meet functional and safety standards.

Visualization’s Impact on Manufacturing Efficiency

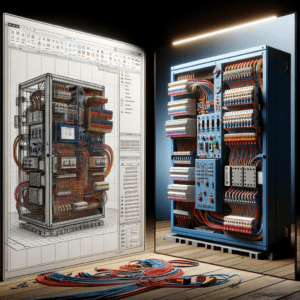

When transitioning from design to manufacturing, visualization continues to play a crucial role. A visual representation of a control panel simplifies the manufacturing process, allowing for efficient assembly and reduced chances of error. Utilizing E3.series, manufacturers can proactively foresee and address potential assembly challenges, leading to smoother manufacturing workflows and higher-quality end products.

In addition to assembly aid, by designing the control panel and switchgear to mirror the exact dimensions of the actual product, the E3.series tool suite provides manufacturers with valuable information that they can use in material processing. Some examples include accurate wire cut lengths, an automatic bill of materials, direct imports to wire processing equipment, labeling machines, din rail and cable duct cutters, and milling machines. Utilizing this manufacturing data increases productivity significantly and cuts out errors by removing manual processes.

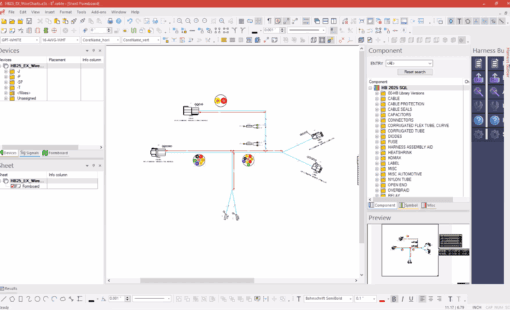

Advanced Visualization Features in E3.series

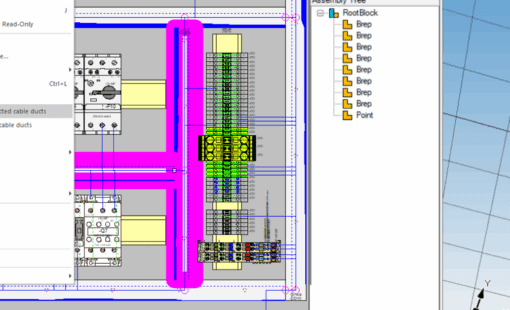

E3.series comes equipped with a suite of advanced visualization features. These include 3D modeling, which allows designers and manufacturers to visualize the panel from every angle, and real-time updates, ensuring that any change in design is immediately reflected in the visualization. Such features enhance the design and manufacturing process and ensure every stakeholder is on the same page, streamlining communication and collaboration. Another advantage of 3D modeling in E3.series is that the designer can work in a 2D representation and still benefit from working in the 3D realm with automatic collision and design checks.

Expanding on the creation of a digital replica, E3.series allows designers to route wires throughout the enclosure automatically. Additionally, E3.series actively performs automatic calculations of the wire lengths, adjusting the values any time a designer moves a component. Other features built into E3.series include various design rule checks. These checks help to prevent overstuffing cable ducts, incorrect mounting placement, and objects in a keep-out area.

Bridging Design and Manufacturing with Visualization

Visualization acts as a vital bridge between the design and manufacturing phases. In E3.series, what is visualized in the design phase can be directly translated into the manufacturing process. This direct correlation reduces misunderstandings, improves accuracy, and ensures that the manufactured product faithfully reflects the intended design.

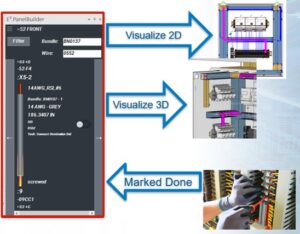

Specifically, the Panel Builder for E3.series plugin is built for panel manufacturers. The plugin provides several features to improve efficiency in manufacturing processes. To start, assembling the panel is simple with the easy-to-follow digitally assisted wiring assembly instructions. The tool gives technicians step-by-step instructions with the wiring path highlighted in 2D and 3D panel displays. Second, for contract panel manufacturers, the wire list import feature makes it quick and easy to populate a panel layout from a connectivity spreadsheet. Additionally, manufacturers can automatically generate a bill of materials and a wire cut list from the E3.series panel design data to help with procurement and estimates. Finally, Panel Builder allows the direct import of the wiring and enclosure information to wire processing equipment, cutting, milling, and drilling machines.

Overcoming Challenges in Control Panel Design and Manufacturing

Both the design and manufacturing of control panels come with challenges, including spatial constraints, compliance with industry standards, and ensuring operational efficiency. The visualization capabilities of E3.series help in preemptively identifying and addressing these issues. Providing a clear and detailed visual representation allows for better planning, error reduction, and adherence to necessary specifications.

Future Trends in Visualization for Control Panel Design

The future of control panel design and manufacturing lies in even more advanced visualization techniques. For instance, we anticipate trends like augmented reality (AR) for virtual panel assembly training and inspections and more automation in the manufacturing and assembly of the control panels. These advancements promise to refine the design and manufacturing processes further, making them more efficient and error-free. At Zuken, we continue to strive to adapt our software to meet the future needs of our customers.

Conclusion

The role of visualization in the design and manufacturing of control panels is indispensable. Tools like E3.series make visualization more accurate and detailed, ensuring the effective use of these representations throughout the design and manufacturing processes. For electrical engineers and contract manufacturers, embracing these tools is not just a step toward efficiency; it’s a leap toward excellence.

For further information, to learn more about how E3.series can revolutionize your control panel design and manufacturing processes with advanced visualization tools, visit our website or contact us for a detailed demonstration.