2021 is FINALLY here! We have so many new Tech Tips planned for this year and we thought it was a good time to reflect on the best-of-the-best Tech Tips from 2020.

Thank you to all of our contributors and visitors who keep this blog thriving. We hope everyone had a fun and safe New Year!

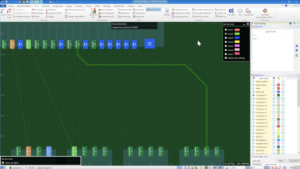

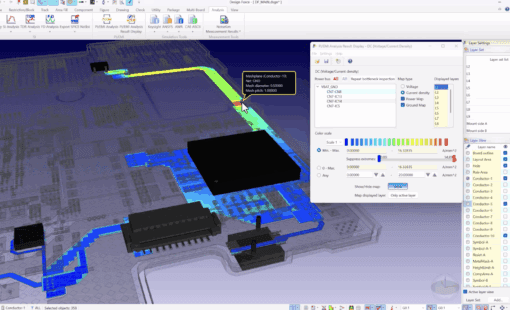

10. Tech Tip: Net Color Display, Design Force

By Brian Gilman

Using color to identify nets, or groups of nets can make it easier to visually identifying nets when routing. The color of nets can be defined in Design Gateway and forward annotated to Design Force. Colors can also be set in Design Force Constraint Browser or by using the “Set Net Color” GUI under the Track tab in the canvas view…

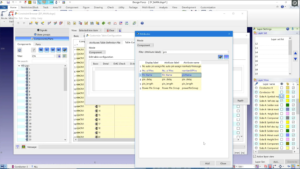

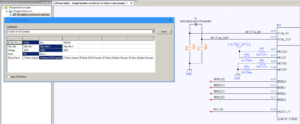

9. Tech-Tip: Creating a Connector Pin Netlist

By Brian Gilman

Checking the pinout of your connectors is an important part of creating your printed circuit board. Checking your pin connections can save you from a costly re-spin of your circuit board. This can be done using the Constraint Browser in Design Force. By default, the Constraint Browser does not show this information…

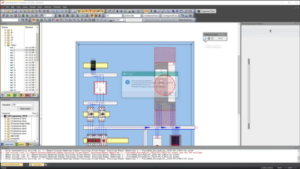

8. Tech Tip: Creating Panel Models and Inserting STEP Files

By Sanu Warrier

This video will show step by step instructions on how to create a basic Panel Model and insert a 3D STEP file. This will display how to align the 3D model with the DXF 2D figure. It creates a 3D Panel model by adding and placing pins onto the model…

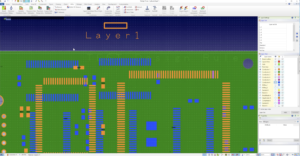

7. Tech-Tip: Checking Data Outside the Board

By Brian Gilman

Board design rule checks only check up to the board outline. If you had dropped or moved some data outside the board outline there was no check for this until now. Checking for data outside the board area can now be done using the [Data outside Board] tool in Design Force 2020…

6. Tech Tip: Managing Variants, part 3

By Tom Warneke

Forward and back-annotation between the parts list and schematic improves design process efficiency and accuracy.In this post, number three of a three-part series, I will show how to compare the schematic and parts list for differences, and then reflect the changes made to the parts list to the schematic…

5. Tech-Tip: Library Database Maintenance to improve your database performance

By Daryl Williams

Please make a backup copy of your library databases before doing these procedures. These functions should be performed by a Library or Database Manager. This video will demonstrate how you can improve your Microsoft Access database performance. We will show how to delete the entries that are in the LOCKINFO table and use the Compact and Repair Database feature in Microsoft Access…

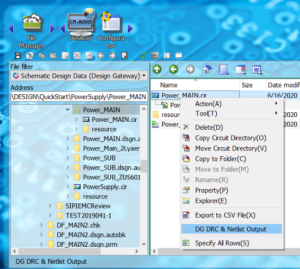

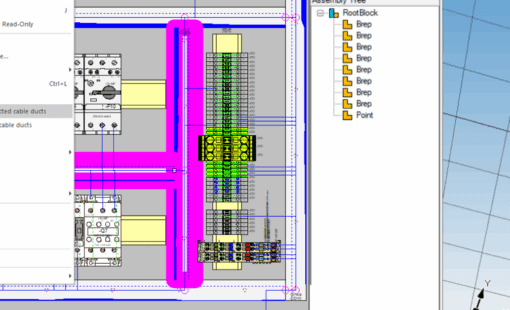

4. Tech-Tip: CR-8000 Combo Command in CR-8000 Engineering Desktop

By Takashi Ichikawa

In CR-8000 Engineering Desktop, we have a function call “CR-8000 Combo Command”. What is the “CR-8000 Combo Command”? This command allows a user to create and put in multiple CR-8000 tool commands together, and continuously execute multiple processes…

3. Tech-Tip: Managing Variants, Part 1

By Tom Warneke

The primary benefit of using variants is to reduce the variety of physical parts to fabricate and inventory, such as bare printed circuit boards. Managing variants can also reduce the number of design and manufacturing artifacts that engineers need to create and maintain…

2. Zuken Halloween Tips and Treats 2020

By Laura Mirto

It is that time of year again, it’s the spooky season. This means the leaves are changing, for some of us. The smell of fall and pumpkin spice is in the air. Halloween decorations are out and ready for trick-or-treaters. Also, this year’s Zuken Halloween Tips and Treats are here!…

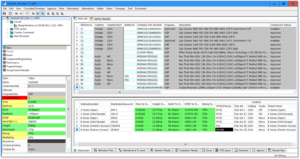

1. Tech-Tip: Managing Variants, Part 2

By Tom Warneke

In this post, I’ll cover utilizing variants that were imported to the Component List Master (CLM) from a schematic. CLM is one of the DS-CR ePDM modules. It is used to manage component lists, often referred to as a bill of materials (BOM)…

Related Resources & Projects

- Blog

- Pages

- White Paper

This eBook describes an MBSE based process for Electrical and Electronic design. The eBook begins with model content and structure with the purpose of implementation and the need for a “design envelope”.