With 2018 just days away, we thought it was a good time to reflect on 2017. The following are the most popular posts on this blog published this year. Thank you to all of our contributors and visitors who keep this blog thriving. Have a happy and safe New Year. We’re excited about all we have in store for you in 2018!

20. The Top 5 Design Issues: ECAD/MCAD Integration, PLM Integration, Data Management, Augmented Reality and PCB Package Co-design

By Dionne Knowles

At this year’s annual conferences (ZIW) across Europe we brought together leading companies in their fields to discuss some the latest electrical and electronic design issues affecting our customers including: ECAD/MCAD integration, PLM integration, augmented reality and PCB package co-design. Companies such as Bombardier, Qualcomm, NTL, Stadler Rail, Schindler and Mercedes-Benz sparked thought-provoking dialogue at the events in Germany, France, Italy and Switzerland during Spring/Summer 2017.

19. Things to Consider Before Investing in a New Electrical Engineering Tool

By Klaus Wiedemann

By Klaus Wiedemann

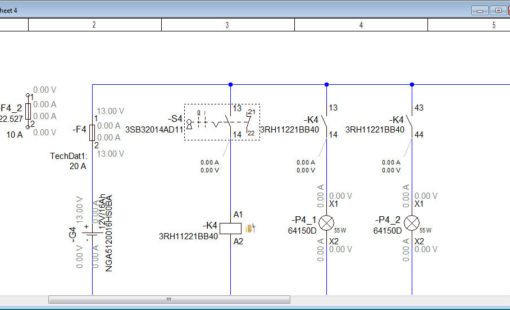

Feeling a bit dazed by the multitude of electrical applications available to you? With Zuken’s E3.series containing a host of products including E³.schematic, E³.fluid, E³.cable, E³.formboard, E³.panel, E³.RoutingBridge, E³.PLCBridge and E³.Wiring Diagram Generator, you may feel overwhelmed on your first approach. Well, you’ve got nothing to worry about! I’ll walk you through and provide you with a guide to figuring it all out.

18. Design Time vs. Admin Overheads: How to Win the Battle by Closing the Gaps

By Thomas Gessner

By Thomas Gessner

No more distractions, please! 45% of our time is already spent on admin. If you’re the average engineer, that is. Techconsult, a German-based analyst firm has just found that almost half of the engineering time of any manufacturing company is spent feeding systems and re-entering data. So it’s no surprise that economists are scratching their heads trying to explain why productivity is declining, despite constantly increasing investments in IT systems.

17. The Not-so-Sweet Side of PCB Designers and Engineers

By Amy Clements

By Amy Clements

The Zuken-sponsored barista cart was the place to be at PCB West this year. Who can resist of cup of Peet’s Coffee – especially when it’s free? As in past years, we asked booth visitors to take a short survey about how they take their coffee. Since tomorrow is National Coffee Day, we thought we’d share the results of that survey with you.

16. A Few Thoughts on Avoiding DDR4 Layout Problems

By Nikola Kontic

By Nikola Kontic

DDR4, the fourth generation of DDR SDRAM technology, is the latest and greatest SDRAM standard and will continue to be until the fifth generation is released. The new standard features a point-to-point architecture that offers superior timing margins. In theory, this should make signal integrity easier to achieve since the designer has more leeway in routing and length matching of the different bit, clock and address lines, assuming operation at the same data rates. But most real-world designs are going to take advantage of DDR4’s ability to double the maximum rate and in this case routability will actually be considerably more challenging than with DDR3.

15. Hardware Architecture Design Becomes the Next Competitive Requirement

By Bob Potock

By Bob Potock

After a lengthy quiet period, the hardware design process is suddenly experiencing numerous changes in the form of design discipline convergence and process extension. The widely used 2D single board PCB detailed design process is being replaced by a 3D multi-board and multi-discipline one. What is happening in detailed design is a great blog topic, but I want to talk about what is happening upstream from the detailed design process – hardware architecture design.

14. Estimate Harness Costs with Harness Builder for E3.series

By Paul Harvell

By Paul Harvell

I recently discussed the genesis of Harness Builder for E3.series with Joe Tito of Wiring Harness News at EWPTE in Milwaukee. Through years of experience working with harness designers and manufacturers, Zuken and I have discovered there was no easy way to quickly and efficiently use a graphical interface to create harness cost estimations and labor times for harness manufacturers. This prompted a three-year project to develop a plug-in tool to the E3.series engineering application.

13. Predictive Failure Analysis Can Improve Product Quality

By Bob Potock

By Bob Potock

We all know that manufacturing yields and costs are the driving force behind product development, rather than product quality. You can buy a Design for Manufacturing (DFM) tool, but try buying a Design for Quality tool – good luck! The best way of measuring product quality is finding out how your product performs in the hands of the customer. But measuring product performance, and quantifying quality, is difficult at best for most products. The good news is that more and more devices are becoming part of the Internet of Things (IoT), which extends the design team’s visibility beyond manufacturing – and that changes everything.

12. Ethernet Emerges as Communications Platform for Next Generation of Vehicles

By Amy Clements

By Amy Clements

Each new generation of automobiles has an increasing number of electronic systems that require communications with other vehicle systems at ever higher speeds. The proliferation of advanced driver assistance systems (ADAS) with fully autonomous vehicles on the horizon has greatly increased the amount of bandwidth that must be transferred between the many processors, cameras, radar units, display head units, etc. on current and next-generation vehicles. Today’s high-end vehicles have 70 or more electronic control units (ECUs) that implement hundreds of distributed functions including bandwidth-intensive applications such as collision lane departure warning systems, collision avoidance systems and automatic high-beam switching.

11. DesignCon 2017: What’s Hot on the Electronics and Engineering Agenda

By Ralf Bruening

By Ralf Bruening

A few weeks ago I was at DesignCon 2017, with the other 3999 people that registered for this annual event; learning about the latest hot topics being talked about in the industry, which included modelling and analysis of high-speed digital circuitry, the latest fast memory architectures such as GDDR5, DDR5 and DDR6, power distribution and power integrity, plus wider engineering issues such as IoT and eLearning.

10. What It’s Like Working for a Japanese Company

By Thomas Gessner

By Thomas Gessner

You tell someone that you work for a software company that provides technology to design high-tech products like rockets and race cars, then the typical image of a hip, cool, young, American company springs to mind, with images of beard-and t-shirt wearing hipster types sitting in a loft-type office, hacking code into their Macbooks while sipping a Doppio Espresso. What will probably not come to mind is the image of a Japanese company, let alone a 40-year-old Japanese software company like Zuken.

9. Zuken and the Art of Motorcycle Maintenance

By Thomas Gessner

By Thomas Gessner

B2B marketing has been my lifeblood for the last 30 years, but over the course of the last 10 years I have gradually built a second skill as a hobbyist motorcycle mechanic. Restoring – or “restomodding”, as petrolheads call it – a comparatively modern 1997 Speed Triple brought me in touch with what we at Zuken are doing from a completely different perspective; one that I felt worth sharing.

8. E3.series Offers French Motorsport Company Liberation from Design Admin and Increased Turnaround

By Sally Powell

By Sally Powell

Zuken welcomes another automotive and motorsport company to the growing club of E3.series users within this exciting sector. French company Techno MAP joins recent members M-Sport, HCI Systems, Teepee Electrical and others who have adopted E3.series based on peer recommendations about the tool’s flexibility, ease of adoption and increased productivity.

7. Top 10 Ways to Improve Electrical and Harness Design in the All New Release of E3.series 2017

By Sanu Warrier

By Sanu Warrier

Zuken, with its E3.series suite, is leading the way in helping companies manage, design and develop products of tomorrow with electro-mechanical complexities such as panels, harnesses, PLCs, and fluid controls. The 2017 release is here to help you be faster, smarter and more effective in being a part of great electrical revolution taking over the broader society.

6. E3.series 2017 Top 10, Part 2: Cross-functional Productivity and Quality Enhancements

By Sanu Warrier

By Sanu Warrier

Cross-functional productivity and quality improvements go hand in hand, it would be a hollow victory to achieve one without the other. Organizations struggle with figuring out where to start amongst the myriad of seemingly endless ‘square ones’. The problem, albeit challenging, is worth solving once you realize the return on investment is huge. The common fallacy is to try to do mechanical design, electrical design, and data management all in one tool set or worse yet, use the best mechanical design tools out there and hope that the quality of the other tools doesn’t matter. It is akin to using a hammer to open a lock, you can do it but a key would be so much easier.

5. Return Vias, Build-up Layers and the Latest FPGAs to Battle Signal Integrity Challenges

By John Berrie

By John Berrie

Luckily, where signals need return vias, component vendors often do most of the work for you. Let’s look at a PCI Express differential pair. First, the standard connector, showing its pinout but not its body; I’ll cover the connector body in a moment. The signal pin assignments are also standardized.

4. How to Beat Google at a Big Industry Challenge: PCB Component Libraries

By Sally Powell

By Sally Powell

Ask any PCB designer what they would put in Room 101, and chances are managing component libraries would be up there. It is an industry challenge with massive cost implications, as engineers spend around half of their development time managing component data. Simply put, less time spent managing component data means more time for product innovation, fewer errors and reduced costs. All things every product development company needs to win them a competitive edge.

3. Using Vias to Maintain PCB Signal Integrity Featuring High Speeds in a 3D Environment

By John Berrie

When traces that carry fast signals are long enough to become transmission lines, return paths are provided by inserting ground and power return planes. These planes pull the magnetic and electric field lines so that they are transverse to the direction the wave travels – a mode called TEM (Transverse Electric-Magnetic). Without TEM, things like characteristic impedance and unit-length delay are unpredictable and that means signal integrity is unpredictable too.

When traces that carry fast signals are long enough to become transmission lines, return paths are provided by inserting ground and power return planes. These planes pull the magnetic and electric field lines so that they are transverse to the direction the wave travels – a mode called TEM (Transverse Electric-Magnetic). Without TEM, things like characteristic impedance and unit-length delay are unpredictable and that means signal integrity is unpredictable too.

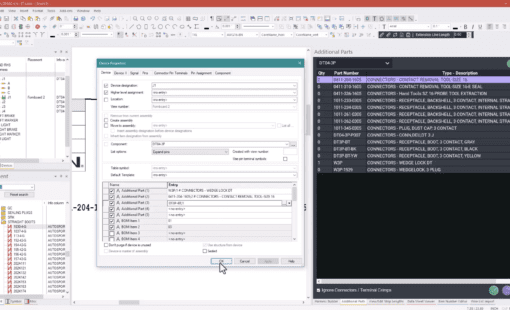

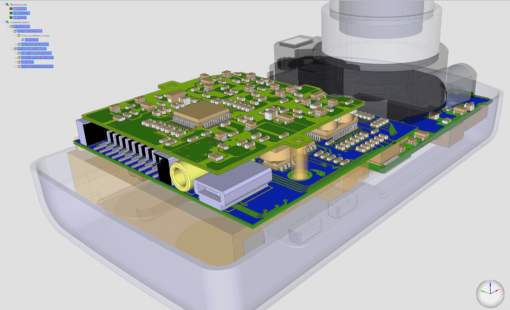

2. E3.series Integration with Creo, CATIA and NX for Wire Lengths and Harness Structures

By Ulrich Prottung

By Ulrich Prottung

Electrical and MCAD integration, if you’re not already doing it, has the potential to save you a good deal of time in the electrical product development process. On the most basic level you can cut out the prototype stage needed for calculating wire lengths. If you’re also working with E3.formboard, as well as the basic module (E3.cable), then you can obtain the entire harness structure.

1. The High-speed Design Challenge of Maintaining PCB Signal Integrity in a 3D Design Environment

By John Berrie

By John Berrie

Not long ago, third dimension issues didn’t figure too much in high-speed design calculations; but signals have become so fast that those vias don’t affect them the same way they did before. Those really fast signals have become part of super-common bus standards that are used in all kinds of products. It’s a PCB design issue that we can’t avoid. Luckily, there are ways not just to address this issue, but to optimize performance at the same time.

Related Products and Resources

- Products

- Products

The traditional practice of mechanical, electrical and electronic engineers working in silos – then consolidating efforts late in the development process – is no longer viable for successful companies. Zuken offers a portfolio of scalable domain data management solutions for PCB and electrical/fluid design plus a range of solutions that integrate design and domain data management into the PLM and ERP world.

- Products

- Products

E3.series is a Windows-based, scalable, easy-to-learn system for the design of wiring and control systems, hydraulics and pneumatics. The out-of-the-box solution includes schematic (for circuit and fluid diagrams), cable (for advanced electrical and fluid design), panel (for cabinet and panel layout), and formboard (for 1:1 wiring harness manufacturing drawings). Integrated with MCAD, E3.series is a complete design engineering solution from concept through physical realization and manufacturing output.