Boost control panel design and manufacturing efficiency, and increase production cost savings

We are excited to share all the details about Panel Builder 2023 for E3.series, the newest plug-in tool for our industry-leading E3.series design platform. Panel Builder is the perfect tool for control panel manufacturers looking to improve their manufacturing process while decreasing production costs. The tool offers two operation modes, one for the designer creating the cabinet layout and connectivity and the other for the operator on the shop floor.

Propel control panel design productivity

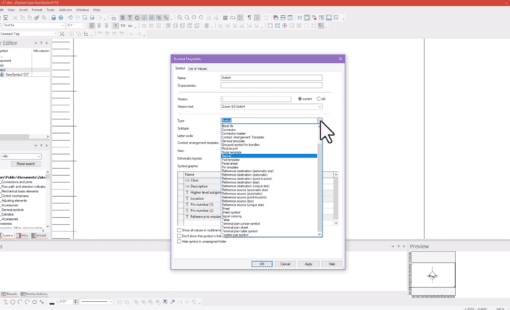

Panel Builder leverages the extensive capabilities of E3.panel, a module within the E3.series platform. Even designers who lack experience in working with 3D models can effortlessly generate a 3D design layout while working in a familiar 2D environment. The tool runs design rule checks for keep-out restrictions, crashing, and clearances for error prevention. Additionally, users can quickly build their libraries using the Component Cloud for E3.series and access free, validated, high-quality electrical components to import directly into their E3.series library. Components include nVent HOFFMAN enclosures and accessories and various electrical parts from Rockwell Automation, ABB, Eaton, Schaffner, and Siemens, among others.

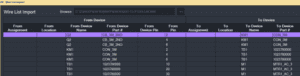

Designers using Panel Builder gain access to tools to assist with the control panel design and cabinet layout. The wire list import tool enables control panel contract manufacturers to populate the project with devices and their connectivity information quickly. This feature is a huge time saver, allowing the designer to drag and drop the devices directly to the panel to create the panel layout. From here, the designer can use automatic routing to intelligently route the panel wiring while adhering to the user-specified design rule requirements.

Furthermore, users can take the drawings to the next step in preparation for production by creating a bill of materials and wiring lists using the included E3.Toolbox plug-in. Instant access to the bill of materials aids in part procurement to prepare for assembly. Furthermore, they can use E3.DrawingNotesManager to easily add production notes from a database of standard notes facilitating effective communication of manufacturing standards and operations.

Jump into the digital era by connecting design to manufacturing

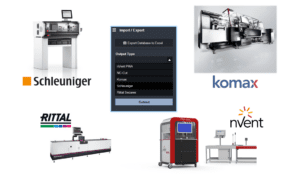

By leveraging the automatic wire length calculations derived from the 1:1 scale wire routing in the panel design, manufacturers can feed wire processing machines with accurate information to match the manufactured product. Panel Builder creates wiring list export files in native formats to provide instructions for wire processing machines from Schleuniger, Komax, and nVent Hoffman, cutting and stripping each wire to the required length. Utilizing wiring processing machines replaces the outdated manual wire length estimation process and eliminates the need to remove excess during installation. This streamlined process reduces material waste, saves manufacturing costs, and improves time efficiency.

Additionally, Panel Builder can generate drilling and cutting machine output files to drive machines like Rittal Secarex and nVent Hoffman NC-CUT for cutting cable ducts, covers, and mounting rails. Manually entering machine instructions or hand cutting can lead to costly waste from human error. Therefore, automating this process reduces time and eliminates manual effort in creating the machine instructions.

Customers with drilling and milling machinery can also leverage the E3.CutOut tool. E3.CutOut extracts the mounting, drill hole, and cut-out information from the panel design to feed this machinery for panel manufacturing. Additionally, Panel Builder includes a customizable hole chart functionality to automatically create a drill hole outline sheet detailing the locations and a table of the specifications for each drill hole. This table includes details of the hole diameter, coordinates, and engineering notes or instructions. Manufacturers can use this sheet for CNC machines or manual drilling.

Empower manufacturing with user-friendly visual wiring instructions

Assisting the shop floor

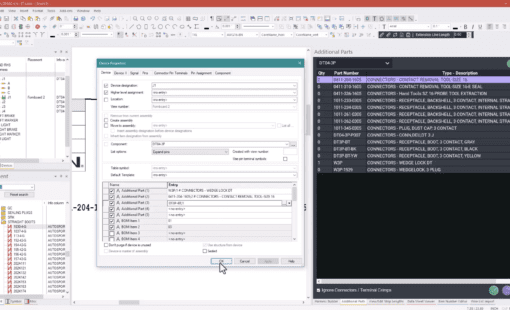

Panel wiring is another area in which Panel Builder helps improve the manufacturing process—traditionally managed using paper copies of the schematics or a wiring to-from list and training. This approach is subject to outdated design instructions or loss of information. Finding a suitable replacement can be challenging if the operator with historical knowledge leaves, not to mention the potential loss of valuable unwritten information. Panel Builder’s Wiring Task Manager replaces this outdated process with a user-friendly digital solution that provides efficient digital tracking.

The Wiring Task Manager uses the detailed design to provide visually guided wire installation instructions to the shop floor through an intuitive interface. The tool guides operators through installation wire by wire, highlighting the path in the 3D panel representation and the schematic. It also provides all the necessary information to make the connection. The control panel’s digital twin makes it easy to deploy technicians with less experience in reading schematics, minimizing the training required.

To further enhance the process, sorting of options based on the panel and location is available to assist the operators performing these manufacturing tasks. Filtering to a specific panel is helpful when connecting multiple panels. For multiple panel assemblies, the Wiring Task Manager intelligently instructs the operator to connect both ends or a single end using the wire to and from destinations. After making the required connection, the operator marks the job as complete, and the Wiring Task Manager will automatically move to the next task.

Data and progress traceability

Live feedback on the wiring progress is crucial when multiple operators are assembling the same build. The Wiring Task Manager writes the build progress of the assembly to a shared project database. This database supplies information traceability and metrics for each manufacturing task. As a result, these metrics provide a better understanding of how long a job takes and who performs each task. Such information is valuable for identifying additional training needs and helps prevent errors and rework.

Caption: Provide technicians with simple and effective wiring instructions.

Implementation of revision control of the design is available with Panel Builder. A controlled release process of the wiring instructions helps streamline the communication between design and manufacturing. The design engineer pushes a released design to the server that the manufacturing team will use for instructions. This streamlined digital process eliminates the steps of sending an email copy or printing a copy of the details to share with production, avoiding potential communication flaws. The server database ensures that the data remains connected and up-to-date with the design. Engineers can also release a delta file to indicate any wiring changes needed from an existing wired panel to match a new design. The updated manufacturing tasks inform the operators how to implement the changes.

Summary

The introduction of Panel Builder for E3.series signifies a significant leap forward in connecting control panel design to manufacturing. This powerful plug-in tool empowers manufacturers to enhance design productivity, streamline manufacturing processes, and optimize overall efficiency. With its innovative features and seamless integration with wire processing machines and cutting machinery, Panel Builder revolutionizes the control panel industry, enabling manufacturers to achieve superior results while reducing costs and saving valuable time. Embrace the future of control panel manufacturing with Panel Builder.

To learn more, check out the website for additional details.

Related Products and Resources

- Products

- Products

E3.series is a Windows-based, scalable, easy-to-learn system for the design of wiring and control systems, hydraulics and pneumatics. The out-of-the-box solution includes schematic (for circuit and fluid diagrams), cable (for advanced electrical and fluid design), panel (for cabinet and panel layout), and formboard (for 1:1 wiring harness manufacturing drawings). Integrated with MCAD, E3.series is a complete design engineering solution from concept through physical realization and manufacturing output.