In the early days, CAD software was little more than a digital drawing board—a tool for creating schematics and layouts that engineers manually updated whenever changes were made. However, as electrical systems have grown more complex, the need for a smarter, more integrated approach has become clear. That’s where intelligent ECAD systems come in.

Unlike traditional CAD tools, an intelligent ECAD system isn’t just a collection of drawings; it’s a dynamic, data-driven platform that understands how components interact, enforces design rules, and integrates seamlessly with manufacturing. Instead of treating a connector as a simple symbol, for example, an intelligent ECAD system knows its pin configuration, voltage rating, and physical dimensions—and ensures correct wiring throughout the design.

Smarter Workflows, Fewer Mistakes: How Intelligent ECAD Eliminates Redundancy and Errors

The real power of an intelligent ECAD system lies in its ability to eliminate redundant work and reduce errors. When you change one view—like modifying a schematic—the system automatically updates all related views, including panel layouts and wiring harnesses. There’s no need to manually check for inconsistencies or track down errors caused by outdated information.

Another key feature is real-time design rule checking. If a wire is too small for the current load or a pin is overloaded, the software flags the issue before it becomes a costly mistake. Built-in collaboration happens is real time—multiple engineers can work on the same project simultaneously, with changes instantly reflected across the system.

But the real game-changer is how these systems integrate with manufacturing. An intelligent CAD system doesn’t just produce drawings—it generates machine-ready data for wire cutting, panel drilling, and automated assembly. That means fewer manual steps, fewer errors, and faster production.

So, in short, an intelligent ECAD system isn’t just about drawing; it’s about designing, validating, and preparing for production in a way that’s automated, accurate, and efficient.

From Concept to Completion: E3.series as a True Digital Engineering Platform

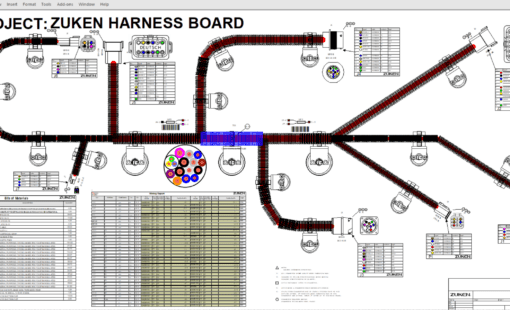

If you’re looking for a real-world example of an intelligent ECAD system, E3.series by Zuken is a perfect case study. Designed for electrical schematics, control panels, and wire harness engineering, E3.series builds intelligence into every layer.

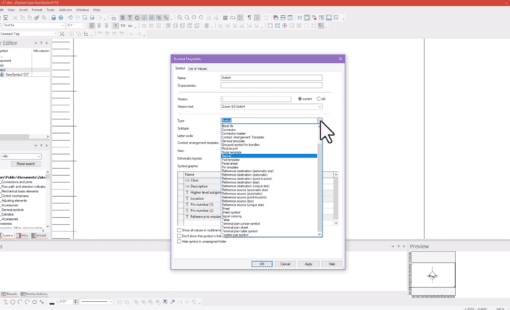

The first thing that sets E3.series apart is its object-oriented design. In E3.series, every component—whether it’s a connector, relay, PLC, or circuit breaker—comes with real-world attributes. That means when you place a component in a schematic, the software already knows its pin configuration, voltage and current ratings, mounting requirements, and connectivity details. These attributes maintain consistency and accuracy across schematics, panel layouts, and wire harness designs. When a change occurs in one view, the software updates it automatically everywhere else.

Seamless Synchronization: How E3.series Keeps Designs in Perfect Alignment

An intelligent ECAD system significantly reduces manual updates and the risk of inconsistencies by ensuring real-time synchronization across all design views. For example, if an engineer selects a circuit breaker for a panel layout, E3.series automatically ensures consistent part representation in the schematic, the 3D cabinet layout, and the wire list. There’s no need to manually update different views or worry about discrepancies—everything stays perfectly aligned.

This extends beyond electrical design. If you use a pump in your project, E3.series automatically keeps the electrical schematic and fluid plan in sync. Any modification—such as changing specifications—appears instantly in all related diagrams, ensuring consistency between electrical and hydraulic systems.

By eliminating redundant work and enforcing design accuracy, E3.series streamlines engineering workflows, reduces errors, and ensures a more efficient, reliable process.

From Design to Production: A Fully Integrated Intelligent Engineering Ecosystem

However, intelligence in E3.series goes beyond just keeping things in sync. The software checks for errors in real time. It prevents pin overloads, incorrect wire gauges, or incomplete circuits. If a designer tries to connect a wire that exceeds a terminal’s ampacity, for example, E3.series immediately flags the issue. This built-in validation catches mistakes early and helps prevent costly rework.

E3.series also makes collaboration easy. It supports multi-user environments so that multiple engineers can work on the same project at once. Whether one person is laying out the control panel while another is designing the wire harness, everyone works with the most up-to-date information. This eliminates version control issues and ensures seamless teamwork.

Another area where E3.series shines is manufacturing integration. The software doesn’t just create schematics—it builds a digital twin of the entire electrical system. Once the design is complete, engineers can send data directly to wire processing machines, CNC panel drilling machines, and automated assembly tools. Instead of manually cutting and routing wires, engineers can export machine-ready data to Komax wire processing machines, reducing assembly time by up to 50%.

The software also integrates with PLM (Product Lifecycle Management) and ERP (Enterprise Resource Planning) systems. BOMs, component selections, and documentation updates flow automatically between engineering and production teams. If a part becomes unavailable, the system flags affected designs and suggests alternatives—preventing supply chain disruptions.

E3.series isn’t just an ECAD tool—it’s a complete electrical design ecosystem. It automates every step, from concept through manufacturing, with accuracy and efficiency.

AI and the Future of Intelligent CAD: Smarter Design, Faster Engineering

As intelligent ECAD systems evolve, Artificial Intelligence (AI) will drive the next wave of automation and efficiency. While today’s tools like E3.series already offer real-time validation, automated updates, and seamless manufacturing integration, AI will enhance these capabilities even further.

Soon, AI could manage component libraries by extracting data from supplier databases and automatically generating schematic symbols and 3D models. It could predict design errors in advance—analyzing thermal loads, signal integrity, and power distribution to flag risks before production. AI-driven design suggestions might also optimize wire routing, component placement, and manufacturability—reducing engineering time and material waste.

Looking ahead, AI may evolve into a true engineering assistant—generating design layouts based on specifications, managing design variants, and syncing with supply chain data for optimal component selection. AI won’t replace engineers, but it will become a powerful augmentation tool—freeing them to focus on innovation rather than repetition.

By incorporating AI, intelligent ECAD systems will make electrical design smarter, faster, and more reliable—today and in the future. With E3.series, that future is already here.

- Blog

- Blog

- Blog

- Blog