Drones, such as the one shown in Figure 1, used to be relegated to hobbies or associated with the military. Technological advances have made them useful in many different everyday applications. We’re starting to see them used as delivery drones, such as the Alphabet Wing and Amazon Prime Air–so what does their future look like?

How Drones Will Be Used

Drones are currently in use in a wide swath of applications. Civil engineers often use them to perform remote visual inspections on bridges and structures that are difficult to reach safely. Manufacturing facilities and warehouses are already using drones for material handling. They are often augmenting traditional machine vision with infrared and thermographic technology. The expectation is that the use of autonomous drones in security, surveillance, and rescue applications will grow.

Drones are increasingly accepted for their use in television, film, and photography. They provide amazing videos and photographs, such as the fantastic view depicted in Figure 2. This all leads to another exciting application of drones: construction, where they support site inspections, progress evaluation, and even time estimates for some material transport tasks. Additionally, drones serve a similar purpose in agriculture, where they can assist in field management, spraying liquids onto crops, and evaluating potential hazards.

Autonomous drones are already used for unmanned delivery, with Amazon Air Prime and Google Alphabet Wing as excellent examples. Researchers and companies are working towards making heavy cargo drones effective and affordable. Companies are also looking at unmanned drones for UAM (Urban Air Mobility), where they serve a purpose similar to an air taxi.

Machine Vision and Autonomous Drones

Autonomous drones have a suite of sensors to enable them to fly safely in their environment. Safe flying can be challenging because they may encounter static and dynamic obstacles. Because of this, one of the core systems in any autonomous drone is machine vision.

Basic sensors such as digital cameras, radar, ultrasound, and lasers provide environmental data interpreted by machine vision AI. For example, a delivery drone like Amazon Air Prime can determine how far away objects are. They can observe motion to predict whether a dynamic object is becoming an obstacle. These drones can also recognize landmarks for delivery by processing the data they receive.

The primary drivers for advances in drone machine vision technology are energy efficiency, footprint, and faster, more accurate algorithms. Researchers are constantly working on sensors that use power more efficiently, and the availability of small, low-power SoC (System on a Chip) solutions is expanding daily.

Artificial Intelligence and the Future of Drones

Autonomous drones already depend on artificial intelligence to navigate and avoid obstacles, as just discussed. As these algorithms improve and progress in image processing, expect to see smarter drones that will easily maneuver in enclosed spaces, crowded urban areas, or near electrical and telecommunication overhead wiring.

For industrial automation, researchers have begun using swarm technology that leverages AI to enable drones to work cooperatively like bees. A key aspect of this technology is their ability to fly in a swarm without striking each other, which requires significant data processing to implement. The expectation is that swarming will become more commonplace, but it has many areas of potential use–including agriculture, as shown in Figure 2.

Power and Structure

Power is always an issue for drones and limits their operating range. The current limitation for the Amazon Prime Air drones is travel within a one-hour radius. Power is especially an issue for larger drones carrying passengers or heavy cargo.

Rechargeable lithium-ion batteries power many drones, which has been a good solution. Still, there is a need for better strategies for the future. Researchers are exploring other approaches for commercial drone batteries, including lithium-sulfur, hydrogen fuel cells, solar energy, lithium-polymer, and various hybrid techniques.

Amazon Prime Air drones weigh about 80 pounds (36.3 kg) and only carry 5 lb (2.3 kg) payloads. Google Alphabet drones are about 10 lbs (4.5 kg) and can handle a load of about 2.5 lbs (1 kg). Structure, therefore, is another crucial factor in payload capabilities and power consumption. And not all drones are small: those intended to carry heavy cargo or transport passengers are larger than our traditional image of a drone.

The size of drones will increase to handle heavier payloads or carry passengers in the future. That means more design will go into developing a better load-bearing structure without adding too much additional weight.

To meet these needs, designers must strike a balance between the drone’s weight (including electronics, battery pack, wiring, motors, and structure) and the power it needs to fly–not to mention the payloads it can carry. Additive manufacturing will enable the production of composite structures with highly customizable material properties, resulting in minimized weight and volume of material used.

Zuken and the Next Generation of Drones

Zuken has several products that support the future of drones. First, there is the complete electrical design platform: E3.series, which supports wire harness, automation, control panel, and switchgear design and serves as a collaborative platform that connects to leading ERP, PDM, MCAD, and PLM systems.

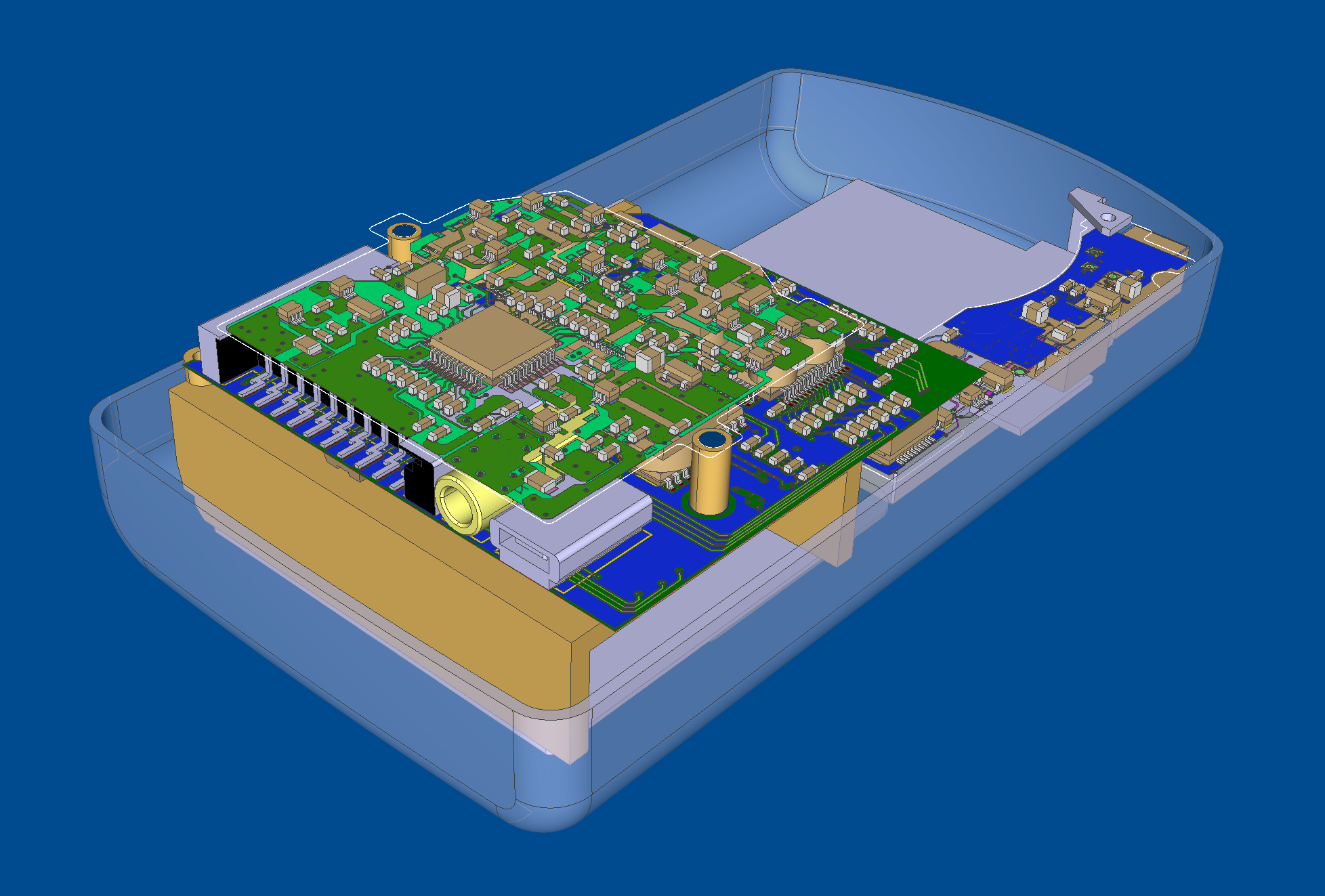

Zuken’s PCB Design products, CR-8000 and eCADSTAR, support both enterprise and desktop design of PCBs using cutting-edge technology and features to support both design and manufacturing. The tool suites are engineered to help with even the most challenging subsystem design and allow electrical and mechanical engineers to work together on projects like the one shown in Figure 4.

Drones are no longer just for hobbies. Every day we find new uses for them, from delivering packages or recording beautiful aerial views to evaluating storm damage and helping find survivors. They are becoming a far more common sight in everyday life. It will be exciting to see what the future holds for them and the technology that brings them to life.

Related Products and Resources

- Blog

- Brochure

- Brochure

- Products

Building a competitive product today is much more difficult than a few years ago. Existing PCB-centric design processes are limited to a single PCB and do not provide the necessary tools for today’s competitive product development environment. PCB-centric design processes are falling behind.