Advances in Wireless Power Transfer Pose New Challenges for Design Engineers

With the transition from fossil energy to electricity, power storage and transfer are critical issues: batteries have a limited capacity and are very heavy, and the good old wire is not suitable for mobile applications. Wouldn’t it be a great idea to transfer electrical power wirelessly, in the same way as we are already charging mobile phones on a charging pad without having to connect a cable?

In principle, transferring electrical power is no rocket science: Instead of using wired connections, Wireless Power Transfer (WPT) relies on electromagnetic fields to transfer power between devices. It is particularly useful for applications for which wires are impractical, especially in electrical vehicles and medical implants or remote sensors.

Consequently, Wireless Power Transfer (WPT) is quickly advancing from a futuristic idea to a widely used technology. Eliminating the need for cables and connectors transforms how we deliver power. Therefore, it doesn’t come as a surprise that the global wireless power transmission market is showing exceptional growth potential: it is expected to grow by more than 25% annually, increasing from $18.3 billion in 2023 to $149.6 billion by 2032.

Transmitting and Receiving: This is How Wireless Power Transfer Works

Wireless Power Transfer (WPT) is the process of sending electrical energy from a power source to a device without using physical wires. WPT systems consist of two components: a transmitter and a receiver. The transmitter changes electrical energy into an electromagnetic field, while the receiver captures this field and converts it back into electrical energy to power the device.

Different wireless power transfer methods each have unique features suited to various applications: Inductive Power Transfer (IPT), the most common method, relies on magnetic fields to transfer energy over short distances, commonly seen in Qi charging pads. Resonant Inductive Coupling builds on IPT using resonant circuits to extend range and efficiency, which are often used in electric vehicle charging. Capacitive Power Transfer (CPT) uses electric fields for compact, high-frequency applications like medical implants. At the same time, Radio Frequency-Based Transfer (RF) transmits low power over longer distances, useful for sensors and RFID tags. Each method balances efficiency, range, and complexity for its specific use case.

Growth of WPT in Medical, Industrial, and Automotive Sectors

It is no surprise, therefore, that Wireless Power Transfer (WPT) technologies are advancing rapidly, transforming industries like electric vehicles (EVs), healthcare, consumer electronics, and industrial automation; in consumer electronics, it is already a standard feature in furniture-embedded transmitters and multi-device charging pads for smartphones, wearables, and IoT devices, with improving charging speeds and range: in healthcare, WPT powers implantable medical devices like pacemakers, reducing reliance on batteries and surgeries; in industrial automation, WPT enhances efficiency by wirelessly powering machines and robotic systems, eliminating cables and reducing downtime; and the automotive industry is adopting wireless charging for electric vehicles (EVs) using resonant coupling and dynamic systems, shaping standards like SAE J2954.

WPT Enablers and Challenges

Advances in several areas have facilitated the rapid uptake of Wireless Power Transfer (WPT) technology, but progress is needed to enable widespread adoption.

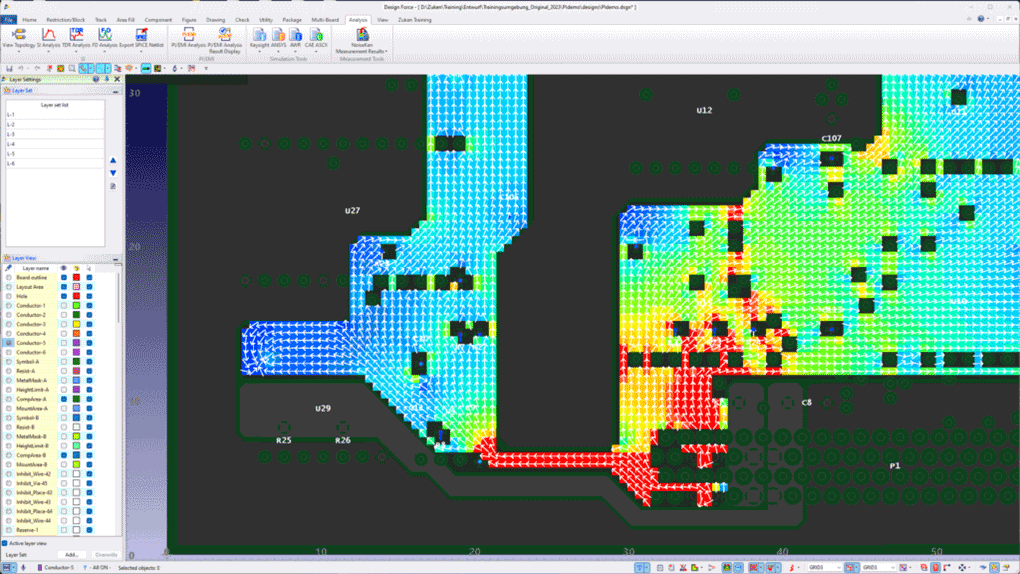

Coil design, materials, and power electronics have significantly boosted system efficiency. Multi-coil setups and high-frequency power converters reduce energy loss, enabling more effective power transmission over longer distances. This is crucial for energy-sensitive applications like EV charging and medical devices. Additionally, innovations in power conversion technologies, particularly with wide bandgap semiconductors such as Gallium Nitride (GaN) and Silicon Carbide (SiC), allow for higher switching speeds, higher voltages, and more compact, efficient designs. These developments are especially valuable in high-power systems like EV charging and renewable energy, where maximizing power density and efficiency is critical.

A major challenge that needs to be addressed is energy loss during transmission, particularly over long distances. This necessitates the use of efficient rectifiers and effective thermal management to prevent heat buildup. Interoperability also remains a crucial concern; therefore, adopting standards like Qi and SAE J2954 will be essential, although country-specific power requirements and proprietary technologies complicate the process. Electrical design engineers play a key role in solving critical issues. They must focus on energy efficiency, interference, and functional safety. These challenges require their expertise and careful attention. As a partner of the global electronics industry, Zuken provides sophisticated tools that help engineers overcome these challenges.

Meeting the Design Challenges with Zuken’s Solutions

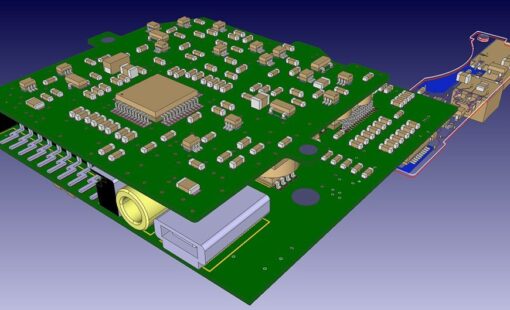

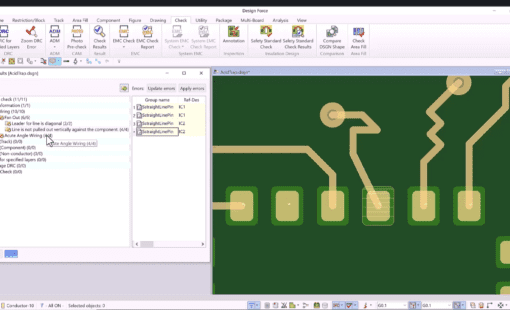

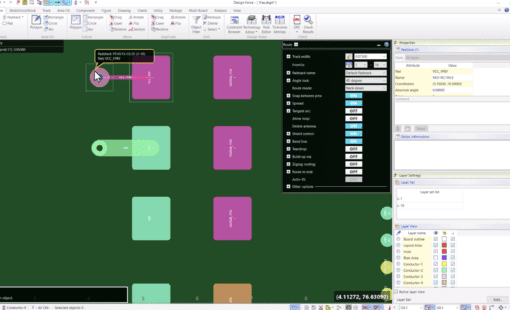

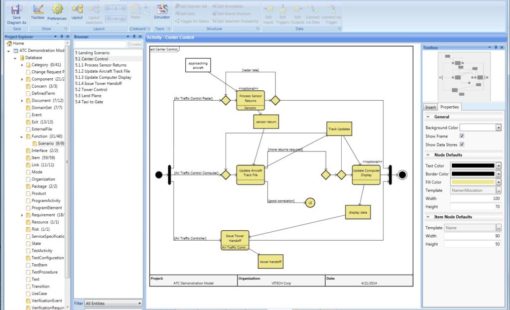

Zuken offers a suite of solutions designed for Wireless Power Transfer (WPT) system development. These tools help engineers design, simulate, and validate complex systems. The GENESYS platform provides a model-based systems engineering (MBSE) approach to optimize WPT architectures for performance and safety. CR-8000 offers advanced PCB design tools to handle resonant circuits, high-frequency components, and EMI. It also includes 3D design and data management features for collaboration. Zuken’s E3.series handles the electrical design, documentation, and production outputs for related wiring systems, ensuring compliance with industry standards. With these instruments and support by consulting services from Zuken’s experts, Zuken empowers engineers to tackle the challenges of WPT system design and development.

Next Steps

Explore how Zuken’s tools can help you design the next generation of wireless power solutions. Download our latest white papers, sign up for a free demo, or watch our on-demand webinars to learn more.

Related Products and Resources

- Products

Digital Engineering requires a model-based design process that begins in Systems Engineering. Zuken acquired Vitech Corporation, a leader in Systems Engineering practices and MBSE solutions, with the intent of implementing an E/E model-based design process.

- Products

E3.series is a Windows-based, scalable, easy-to-learn system for the design of wiring and control systems, hydraulics and pneumatics. The out-of-the-box solution includes schematic (for circuit and fluid diagrams), cable (for advanced electrical and fluid design), panel (for cabinet and panel layout), and formboard (for 1:1 wiring harness manufacturing drawings). Integrated with MCAD, E3.series is a complete design engineering solution from concept through physical realization and manufacturing output.

- Products

Building a competitive product today is much more difficult than a few years ago. Existing PCB-centric design processes are limited to a single PCB and do not provide the necessary tools for today’s competitive product development environment. PCB-centric design processes are falling behind.