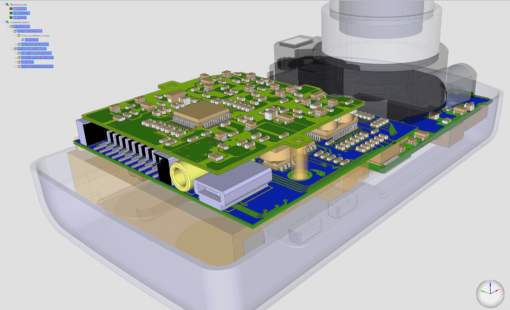

Single fabrication and assembly checking platform for any board technology, including rigid, flex, embedded components, and LTCC

The CR-8000 ADM system checks that designs are produced in accordance with component mounting and manufacturing specifications early in the design process, and concurrently as the work progresses. The system facilitates sharing personal expertise and it efficiently manages the growing number of design rule checks needed to ensure manufacturability.

Single fabrication and assembly checking platform for any board technology, including rigid, flex, embedded components, and LTCC

Concurrent verification of manufacturing rules any time in the design process through an embedded checking engine

Over 900 rules in 96 groups to improve product quality and yield. Easy extension and update through wizards

Automatic generation of spreadsheet reports with screenshots for documentation and communication

Ensure manufacturabilty through an embedded check engine

The check engine for ADM can handle more than 900 individual checks in 96 groups. These cover both bare board manufacturability and component mount checks. It is even possible to automate the visual check process

The Rule Manager at the heart of the ADM system contains more than 900 rules, and is accessible using a standard web browser. Design and manufacturing parameters held in an XML database are downloaded via this familiar interface. The user can also add information to the rules

ADM bridges the gap between the layout and manufacturing phase by enabling designers and DFM engineers to exchange and run rule sets using a common check engine. Users can also review and confirm that all required rules have executed and signed-off to release the design for manufacturing.

Design Force combines traditional 2D design with native 3D design and the latest human interface techniques, accelerated graphics and almost instantaneous rendering and refreshing. It is the fastest, most effective PCB design solution available today. Design Force enables design teams to layout their designs in the context of a complete system or product.

PCB Design for Manufacturing (DFM) enables designers to handle the increasing complexity and diversity of today’s PCBs, while ensuring high final product quality, and accurate outputs for the manufacturing processes. With a robust set of features for data preparation and embedded verification to ensure manufacturing specifications are met...