Prepare and verify manufacturing data

PCB Design for Manufacturing (DFM) enables designers to handle the increasing complexity and diversity of today’s PCBs, while ensuring high final product quality, and accurate outputs for the manufacturing processes. With a robust set of features for data preparation and embedded verification to ensure manufacturing specifications are met, DFM Center addresses the challenges of the manufacturing process.

Prepare and verify manufacturing data

Perform fabrication and assembly checks

Optimize manufacturability with powerful post-processing functionality

Create comprehensive manufacturing documentation with automatic drill table generation

Find out more about our manufacturing preparation software

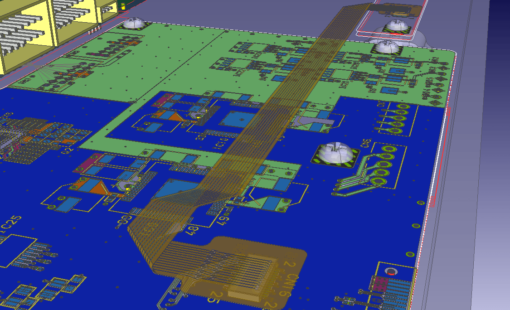

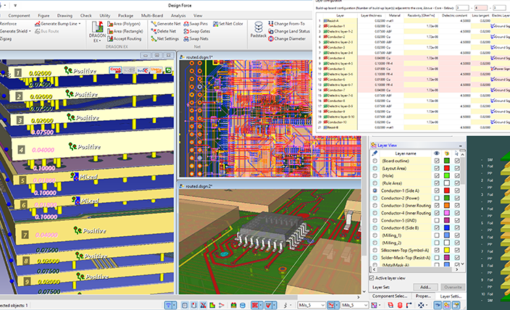

Prepare and verify manufacturing data by paneling up a single or combination of PCBs with real-time manufacturing DRCs.

Additional fabrication and assembly checks are applied dynamically based on any manufacturer’s specifications. This allows you to design-anywhere-manufacture-anywhere.

With powerful post-processing functionality, designers apply the necessary additions and modifications to the design, such as automatic copper flooding of the complete panel.

Additional fabrication and assembly checks are applied dynamically based on any manufacturer’s specifications. This allows you to design-anywhere-manufacture-anywhere.

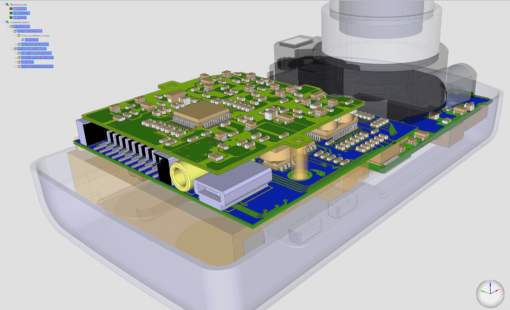

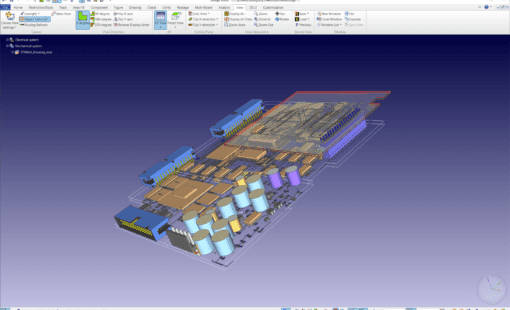

Design Force combines traditional 2D design with native 3D design and the latest human interface techniques, accelerated graphics and almost instantaneous rendering and refreshing. It is the fastest, most effective PCB design solution available today. Design Force enables design teams to layout their designs in the context of a complete system or product.

Find out more about CR-8000 DFM Center via our webinars, blogs, press releases and more...