Advanced 2D and 3D Control Panel Design

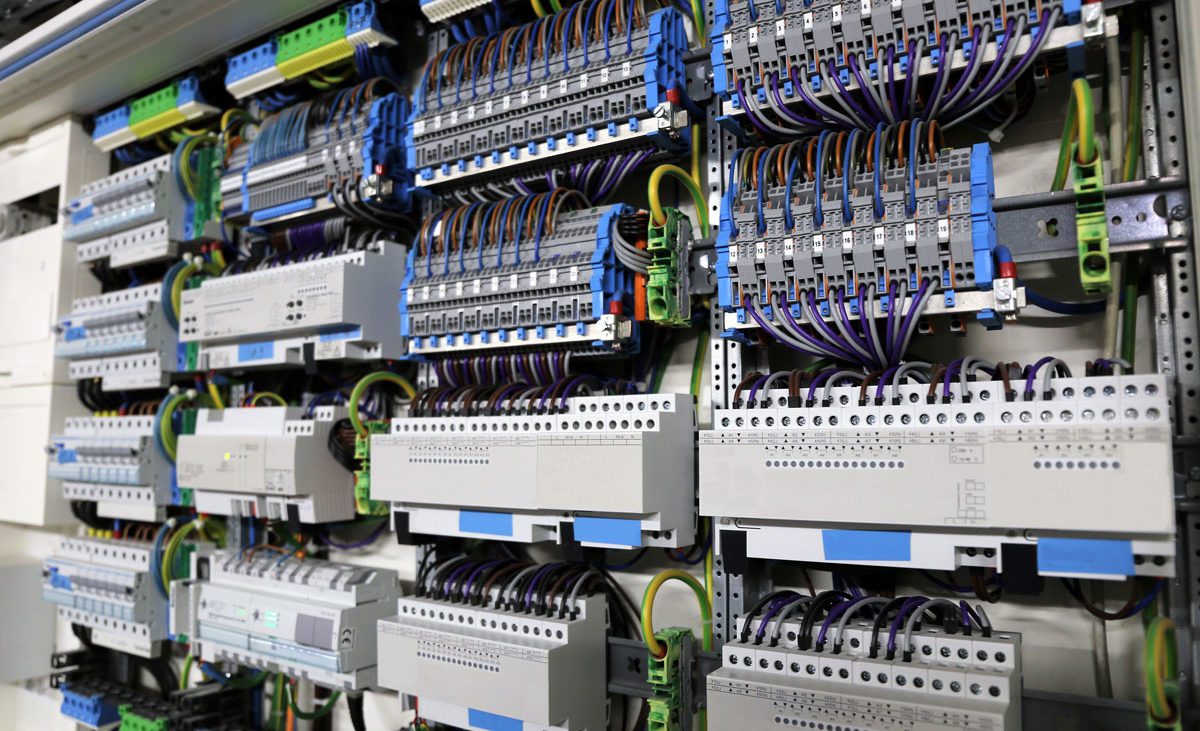

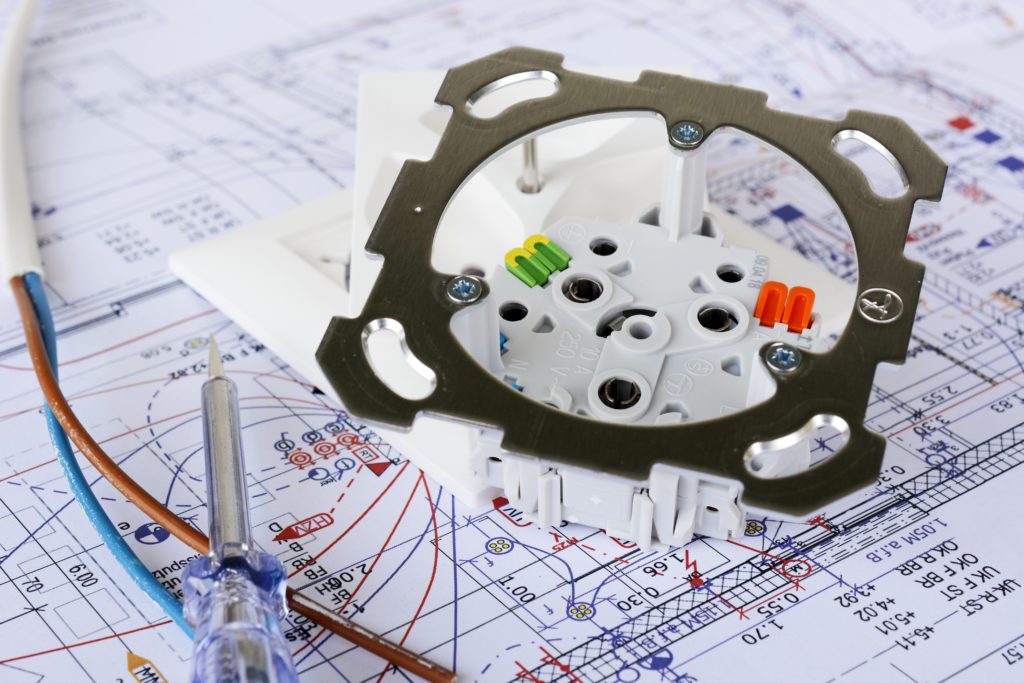

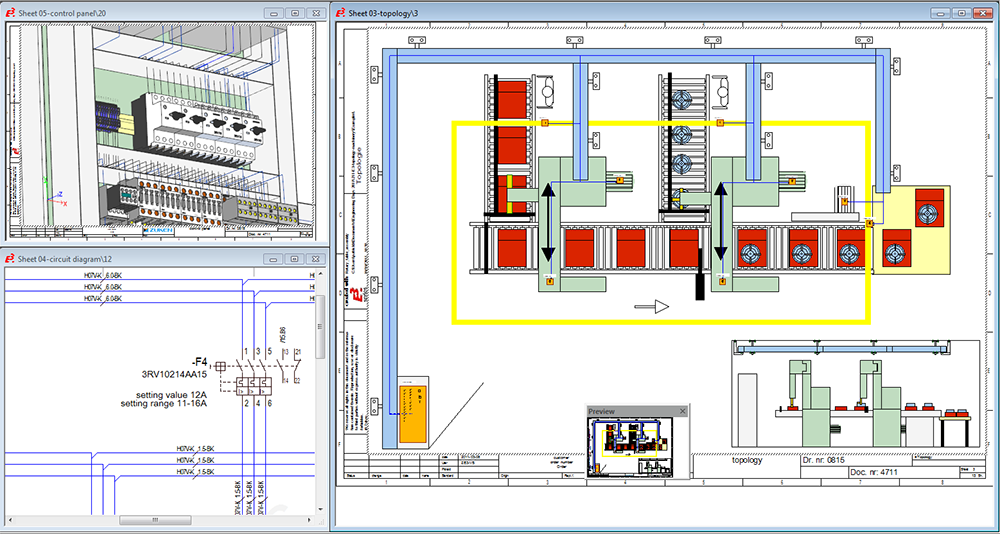

E3.series complete cabinet design solution (E3.panel) offers a connected solution to efficiently create designs to drive manufacturing, assembly, and service operations – unlocking the true potential of digitalization. Engineers can easily layout components inside panel enclosures in 3D and 2D at a 1:1 scale with automatic design rule checks. E3.panel has dynamic integration with E3.schematic and E3.cable modules. Users can effortlessly navigate between the modules, and any changes in either reflect immediately.

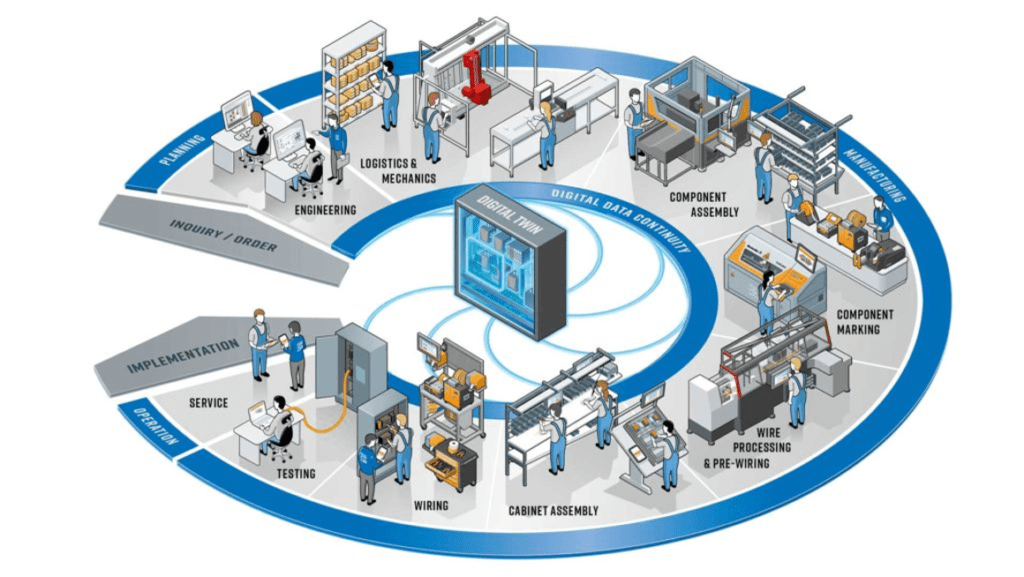

Smart Cabinet Building Initiative

Zuken, Weidmüller, Komax, and Armbruster Engineering have launched the SMART CABINET BUILDING initiative to provide new solutions in electrical cabinet manufacturing. This initiative provides customers with end-to-end solutions for the electrical cabinet design-to-manufacturing process utilizing digitalization.

Learn MoreDesign in 2D for Results in 3D

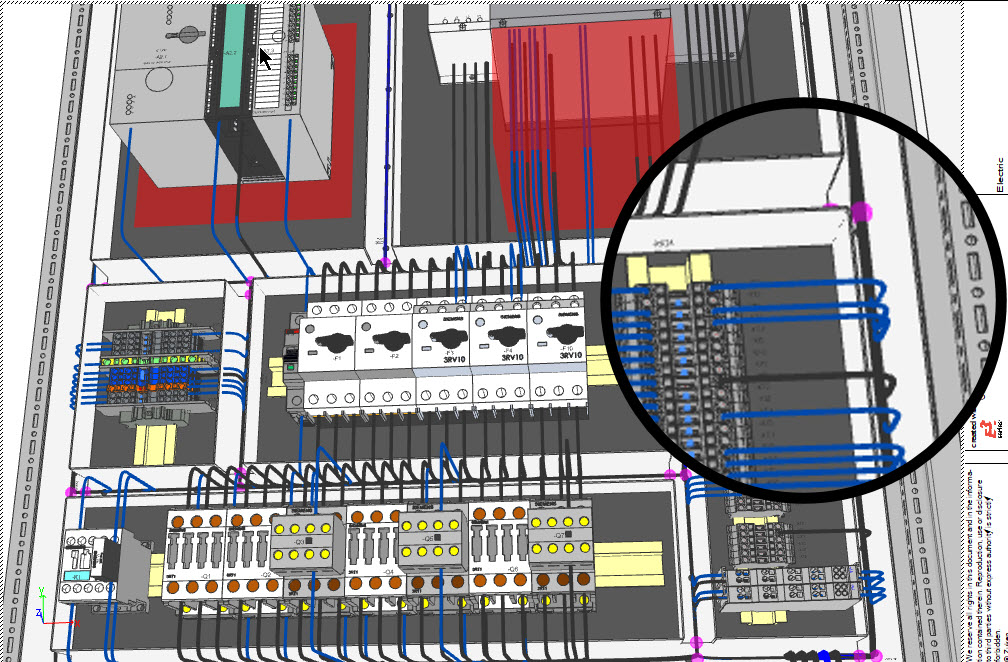

E3.panel provides the game-changing ability to work in a familiar 2D environment while still taking advantage of all the benefits 3D cabinet design offers. Electrical engineers predominantly create logical designs in 2D. Although designing in 3D has massive benefits, the overhead of learning complex 3D mechanical tools is a significant drain on productivity for cabinet designers.

The E3.panel unlocks substantial time savings with the most practical solution for electrical engineers. Any change simultaneously in the project occurs in 2D and 3D without forcing a rigid workflow. The option to produce complete 3D representations and multiple 2D views ensures clear and accurate documentation is only a click away.

Interactive Placement and 3D Collision Control

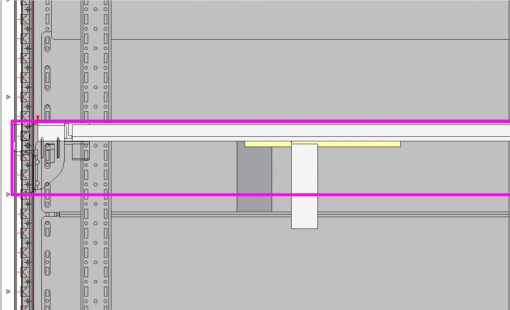

Intelligent automatic snapping points help designers place parts in their correct location. The active design rule checks with keep-out and height restrictions prevent collisions. Using JT, VRML, or STEP AP203/214, all 3D data is readily transferable to 3D mechanical systems.

E3.panel simplifies mechanical collisions checks with the use of simplified models along with 3D models for enhancing visualization. This functionality enables full digital mock-ups to assess spacing requirements, clash detection, and error prevention.

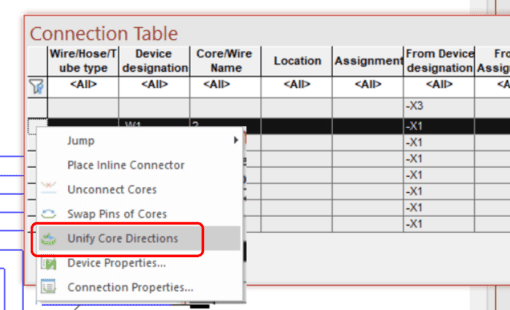

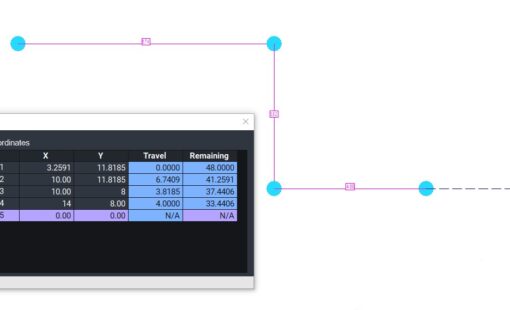

Automatic Wire Routing

The automatic wiring option in E3.panel+ eliminates many common challenges of traditional cabinet design. The automatic wiring considers wiring duct space, current chains, wire size, and logical connectivity in calculating the routes. The application checks duct fill capacity for wires and reroutes as required to ensure wiring standards are maintained.

The advanced algorithm with configurable options ensures consistent wiring to match the requirements of diverse cabinet applications. The 1:1 scale of the E3.panel provides accurate wire lengths and wire termination details to feed cutting-edge automated manufacturing processes.

Auto-Sync schematic and Cabinet

The physical layout of the cabinet is a representation of the logical connectivity in the schematic and not a disconnected artifact. E3.series platform with its connected single source project philosophy automatically ensures consistency across multiple drawing types and views.

For instance, changing a terminal part number replaces the cabinet model automatically if the mounting and space allocation is valid. Any parts added in the cabinet and instantaneously available in the schematic to create logical connections. The versatility of starting design in the schematic, cabinet, or rough functional layout helps teams incorporate the best practices into current design processes.

Learn MoreClearance and Mounting Checks

The cutting-edge ability to define 3D data with detailed mounting parameters, clearance requirements, and space allocation assists design teams in creating accurate cabinet layouts. The interactive placement options run active design rule checks to improve quality and consistency.

E3.series provides live feedback for valid mounting locations and rejects incompatible parts from mating with each other. The 3D envelope of the components detects collisions while moving and placing elements in the cabinet. Designers save time with options to place multiple components at once.

Data exchange with PLC programming environments

Although complex and challenging, PLCs are ubiquitous in automation and control applications. E3.PLCBridge is an E3.series application used for the bidirectional data exchange between E3.series electrical and fluid projects and PLC programming software. Connecting to PLC configuration solutions from manufacturers enables a streamlined digital workflow.

The initial and incremental communication options ensure up-to-date data across applications. Industry-standard communication options like the AutomationML interface allow the engineers to connect logical wiring and PLC configurators to eliminate errors and avoid rework.

- Hardware module type

- Item designation

- Physical addresses

- Symbolic addresses

- I/O comments

- Start address

- Component and device attributes

- Pins and their configuration

- Module layout

- AutomationML Interface (a format specified by IEC 62424)

- Certified interfaces for E3.seriesare available for Siemens TIA Portal, Mitsubishi MELSOFT Navigator, and OMRON CX-Programmer

- In addition, any PLC programming software that supports the AutomationML format can be used to import/export data

- B&R Automation Studio

- ABB Automation Builder

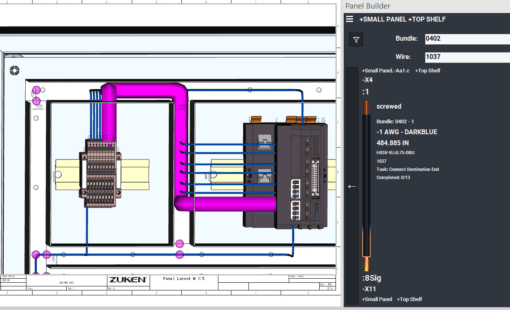

Support Control Panel Manufacturing

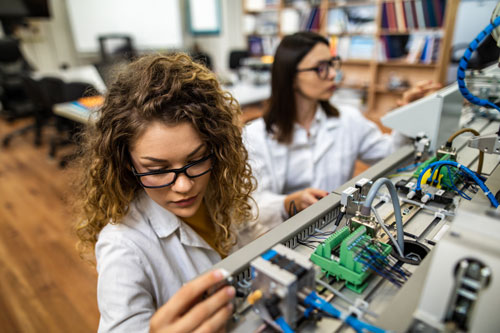

Manufacturers can leverage the information automatically available from the accurate 1:1 scale 3D control panel designs that E3.panel offers. When adding the automatic wire routing and length calculations, manufacturers have everything they need to help feed their manufacturing equipment which introduces production automation and increases efficiency.

Panel-related additional tools like Panel Builder for E3.series and E3.CutOut connects detailed design to manufacturing to communicate this useful information and drive manufacturing processes.

Learn MoreRelated Tools & Resources

E3.schematic provides electrical engineers with an easy-to-use solution for designing and documenting electrical systems, including schematic and wiring diagrams. The module helps by automating common tasks to reduce design time in areas such as intelligent connections, part sections, and reporting. Its object-oriented architecture provides an integrated and consistent design approach to help eliminate errors, improve quality, and reduce design time.

E3.schematic uses an intelligent component-based parts library and built-in design rule checks to save valuable time and prevent user errors. The module manages all design data, such as a bill of materials, connection lists, assembly instructions, terminal plans, and datasheets. Additional features of E3.schematic include the ability to design a hierarchical system design, handle product design variation, cross-reference, and support industry standards.

The E3.series suite contains productivity-focused tools for various activities like design, project management, document management, and collaboration. These tools streamline engineering processes, automate repetitive tasks, and simplify collaboration among engineers and other stakeholders. Helping electrical engineers manage their work and increase efficiency.

E3.panel is a software application that provides various tools to streamline the design-to-manufacturing workflow, reduce errors and rework, and deliver high-quality control panels to clients. Providing the ability to connect to leading intelligent cabinet manufacturing machines with flexible data export options. E3.CutOut can extract mounting and cut-out information from designs to drive automated drilling and milling machines.

Additional E3.series tools for next-generation manufacturing automation can capture accurate wire lengths and termination information. The digital data drives highly automated wire-cutting and processing machines from vendors like Schleuniger, Komax, and Argus. The detailed, consistent control panel design process in E3.series produces clear assembly instructions and automation options.

Managing electrical projects and libraries can be challenging due to the vast amount of data involved. The solution is to integrate with software tools that can help manage, control, and store electrical project and library data. DS-E3 is designed specifically for electrical design and manufacturing engineers. It provides validated libraries, design data, and BOM information, supports intelligent design configuration and reuse, and generates a 100% BOM and documentation from a 150% BOM. Cloud Collaborator for E3.series is a cost-effective solution to manage, control, and securely store E3.series projects for customers working with projects at a single-user level. The Zuken Component Cloud for E3.series provides online access to free, validated, high-quality electrical component data to users of E3.series. Having access to on-demand components saves time with jump-starting electrical designs.

The E3.series tool suite offers several tools to run verification and simulations on the project designs, including E3.eCheck and E3.WiringChecks. These tools help to analyze electrical schematic circuits functionally, check for wire sizing errors, and test fully wired machines or control cabinets. E3.SaberFrameway allows design engineers to create right-first-time robust wire harness designs, with direct integration for the multi-domain simulation of cables, wire harnesses, hydraulics, and pneumatics. The simulation and verification tools allow engineers and designers to virtually test and validate designs before building physical prototypes, reducing the number of physical prototypes needed and ultimately accelerating the time to market.

E3.series offers a suite of redlining, analysis, and viewer tools, including E3.viewerPlus, which integrates directly with dedicated software systems for managing exploded assembly drawings, wiring diagrams, and stock information. Redlining software allows teams to review, mark up, and comment on project documents and designs, streamlining the review process and ensuring all stakeholders are on the same page. E3.ConnectivityBrowser is a plugin that allows for standardized visualization of the defined connectivity across schematics and views—finally, E3.HarnessAnalyzer is a tool that allows for efficient viewing, analyzing, validating, and commenting on harness design models and related drawings, enabling OEMs to optimize their process chain and collaborate with their suppliers.

Evaluate Zuken Software

Start Your Test Drive Today

- Test Drive

- Test Drive

- Test Drive

Related Resources

Find out more via our webinars, blogs, press releases and more...

- Blog

- Press Release

- Press Release

- Press Release