Empowered Design Tools

The 2020 release of Harness Builder for E3.series is packed with productivity and automation tools to make this release the best yet. The majority of the features are a direct result of the feedback Zuken USA received from our customers. As a result, we have come closer than ever to a perfect solution for wire harness design and manufacturing teams.

The latest developments of Harness Builder for E3.series are driven by the goal of creating a highly accurate wire harness design that requires minimal manual input and can drive downstream testing and manufacturing automation. It has never been easier or faster to use a single solution to go from quotation to manufacturing within a single solution.

Empowered Design Tools

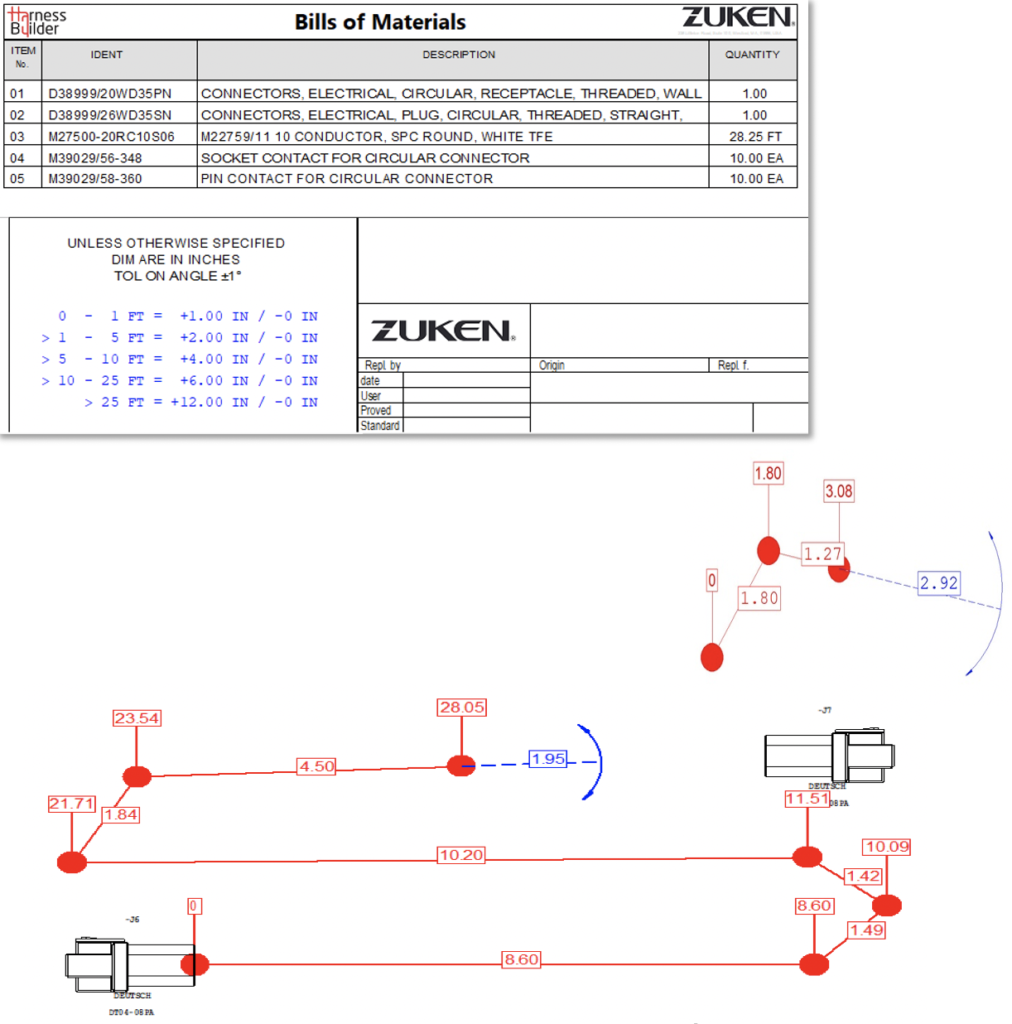

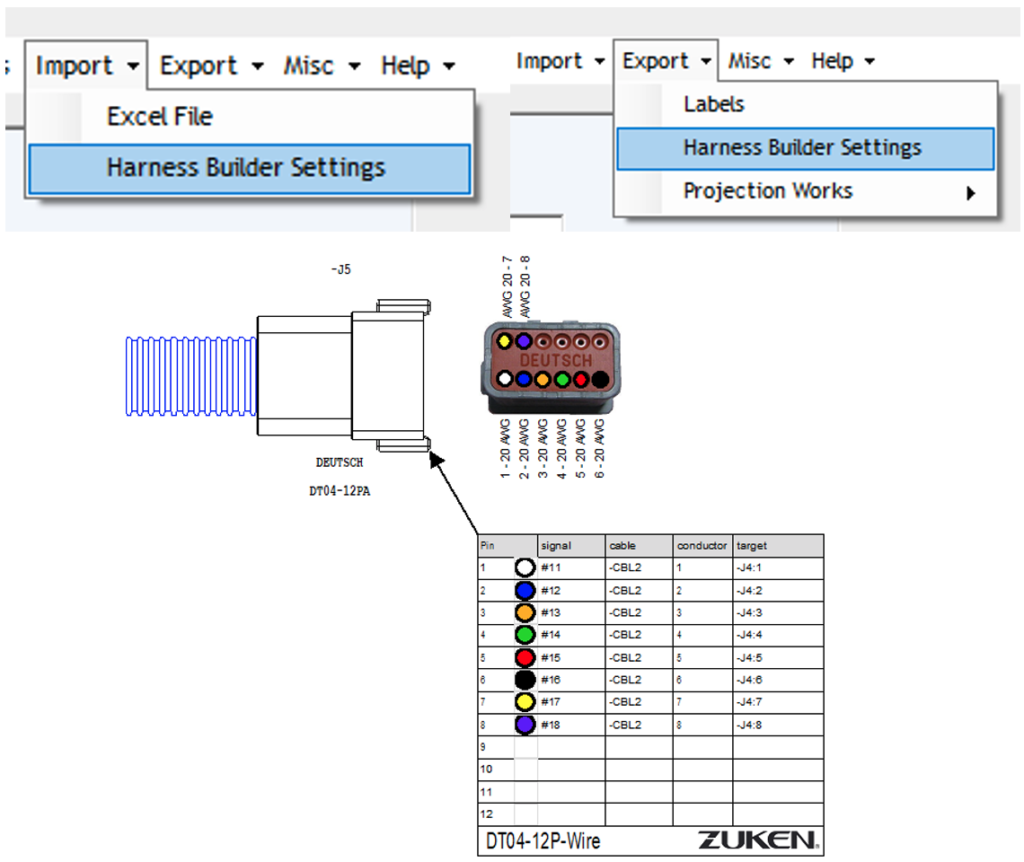

Automated Harness Detailing

Expanded Automated Report Generation

Testing and Manufacturing Automation