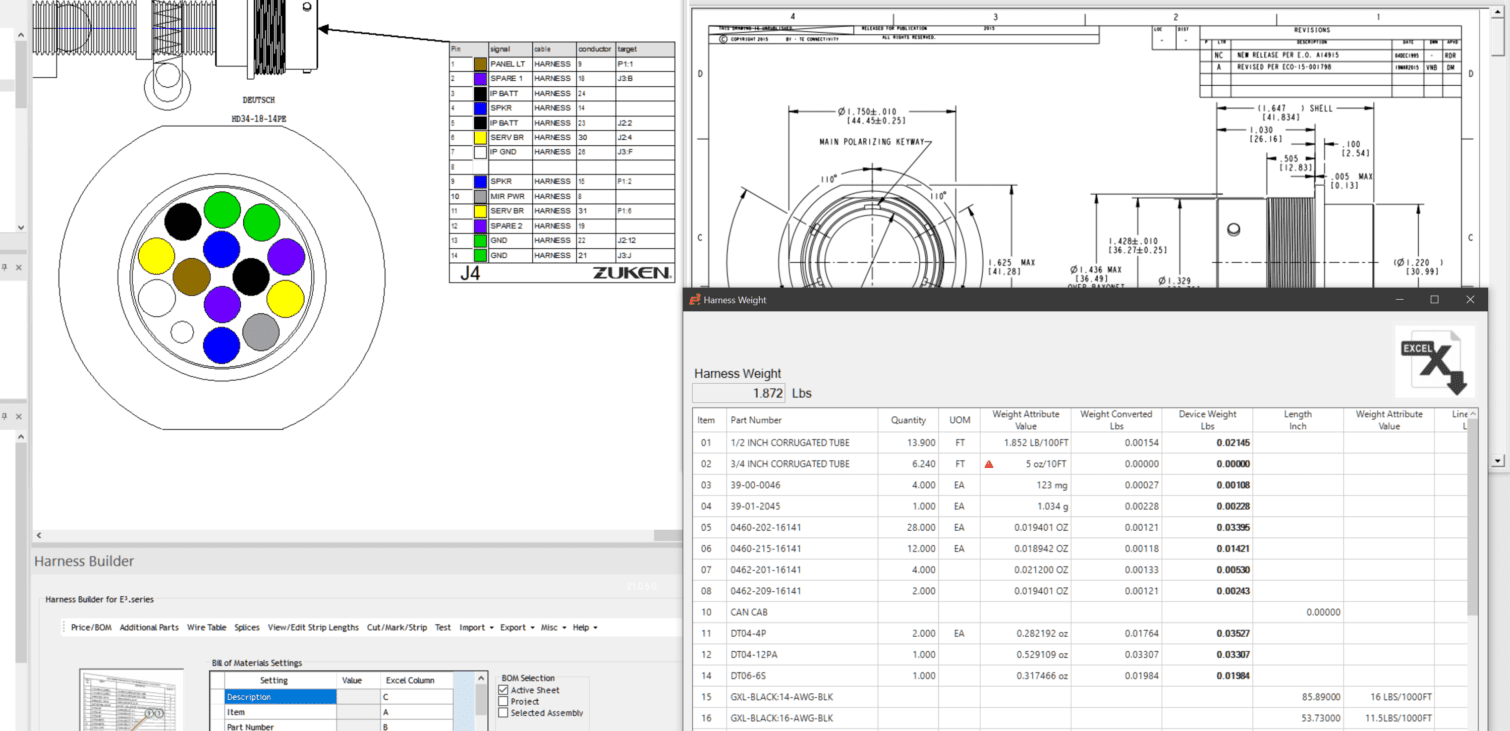

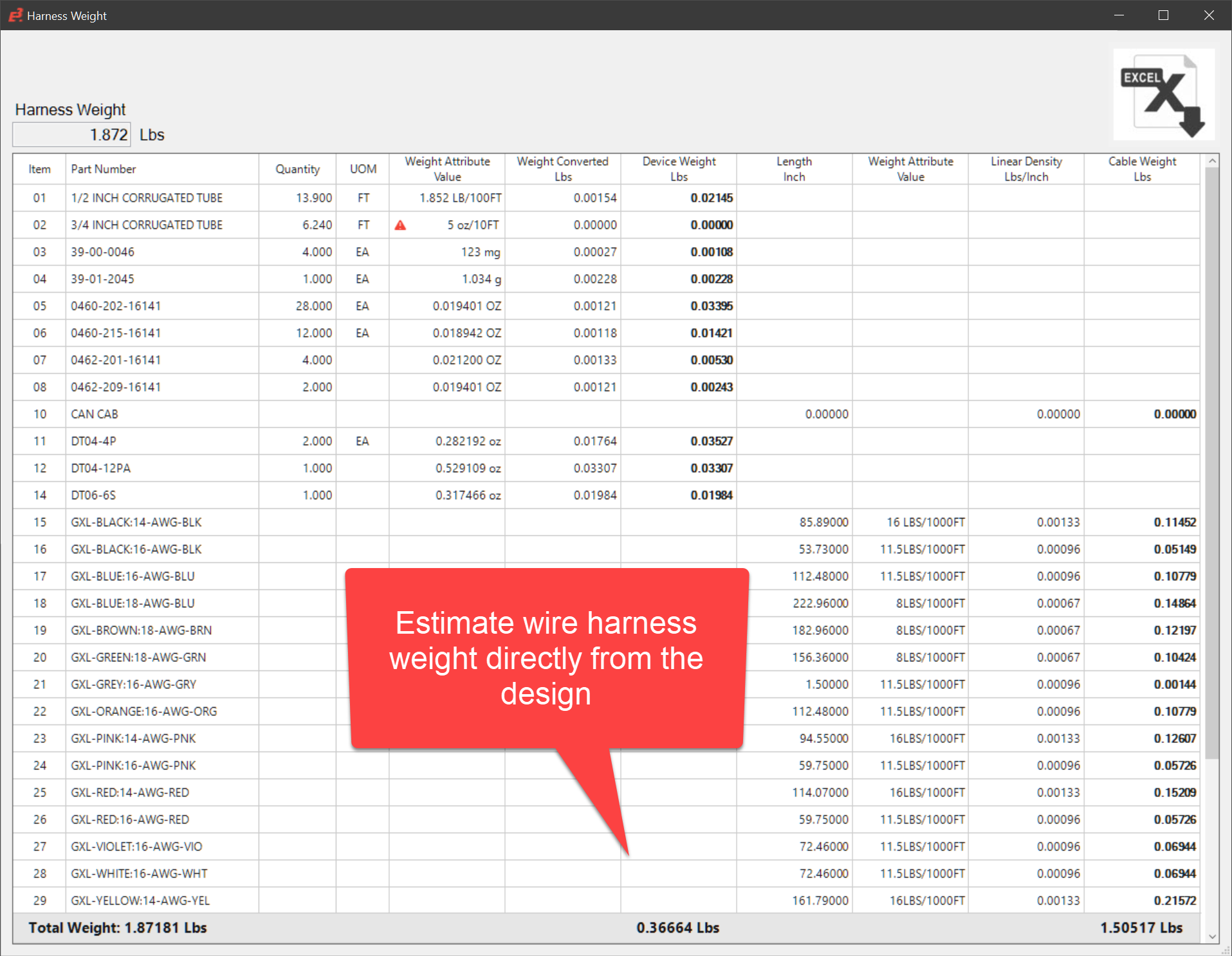

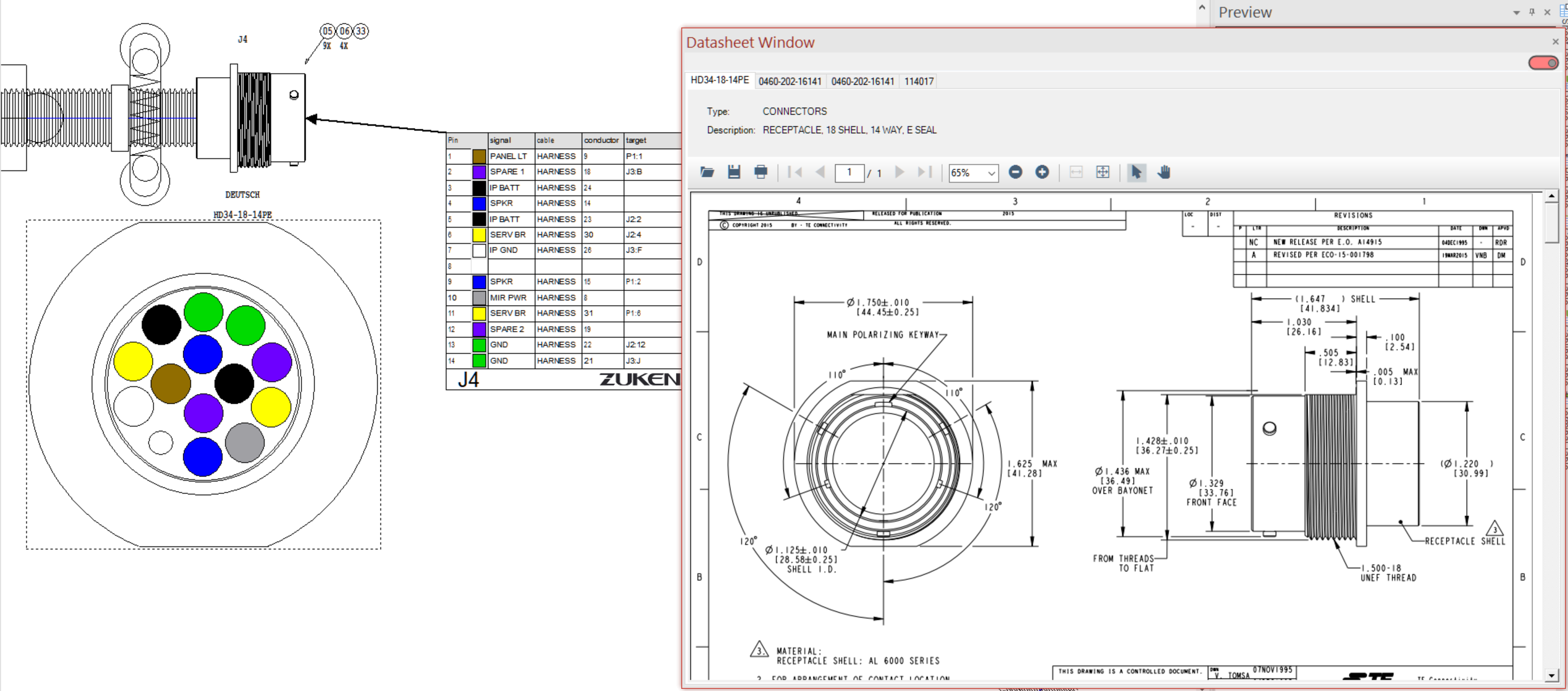

Wire Harness Weight Estimator

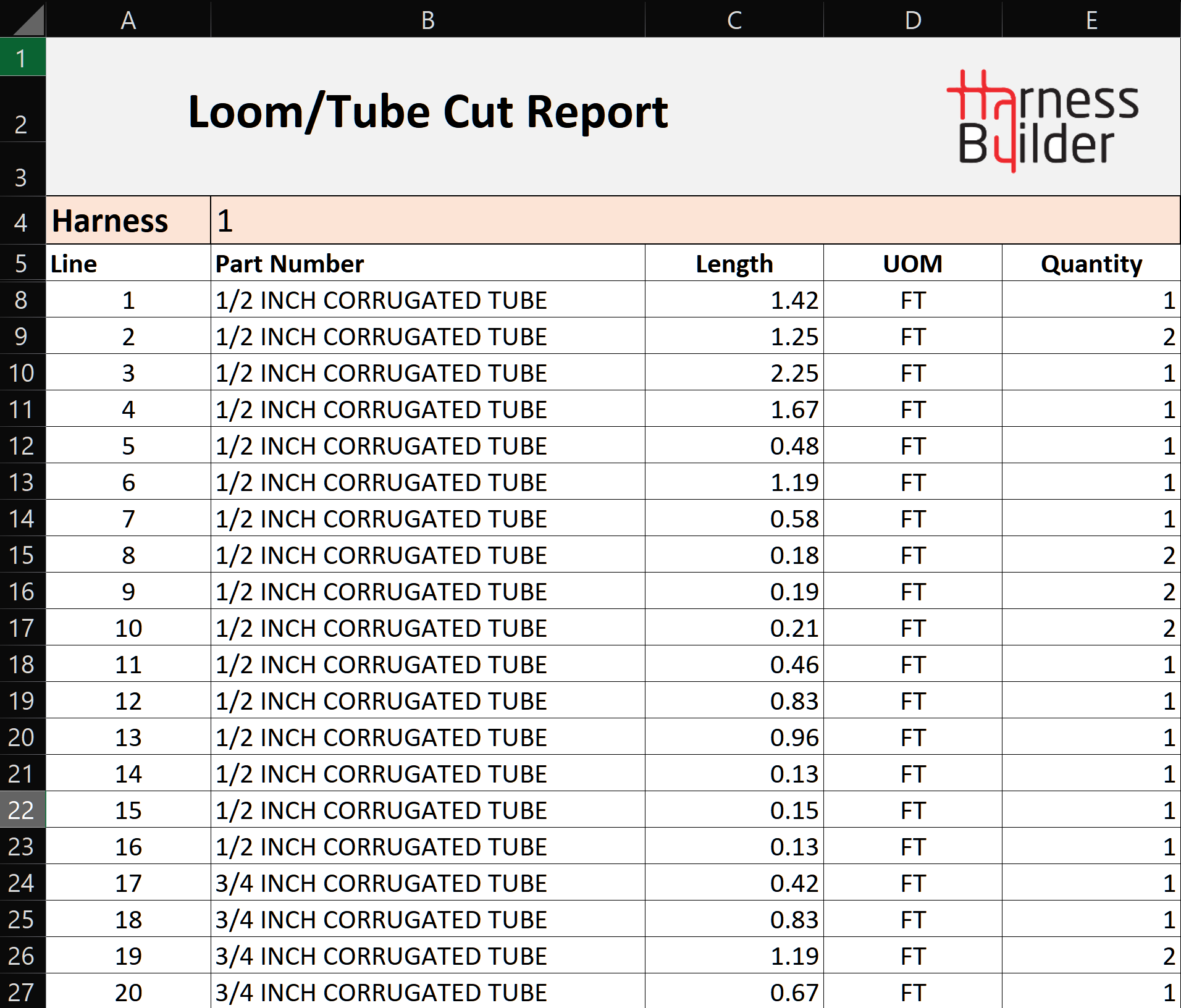

Harness Builder for E3.series introduces the brand-new wire harness weight estimator to empower wire harness engineers to track the weight of a harness throughout the design cycle. There are many factors influencing the weight of a wire harness. The estimator considers the weight of wires, tubing, cable protection, and all harness components in a formboard drawing. For instance, the estimate will include the weight of connector pins, coverings, seas, and other accessories to provide the most accurate estimate. The harness weight estimator handles multiple measuring units to handle a wide range of component and design types.