Electrical and Mechanical Collaboration

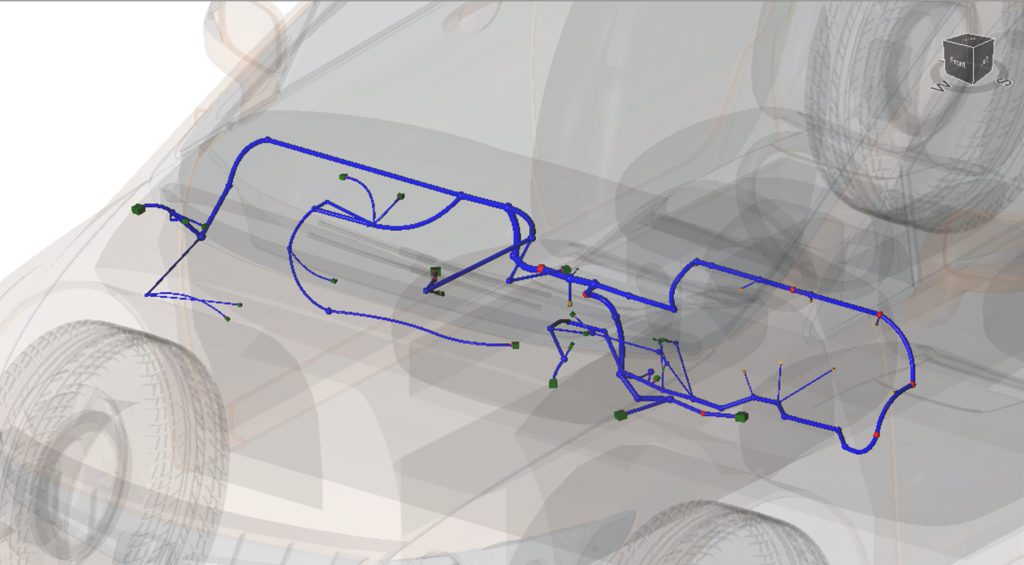

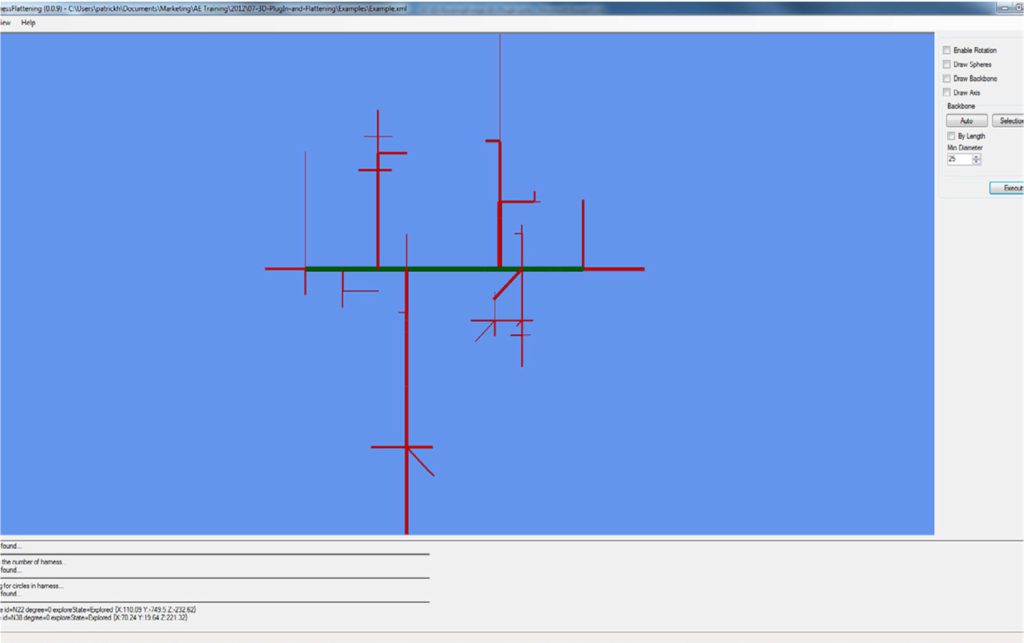

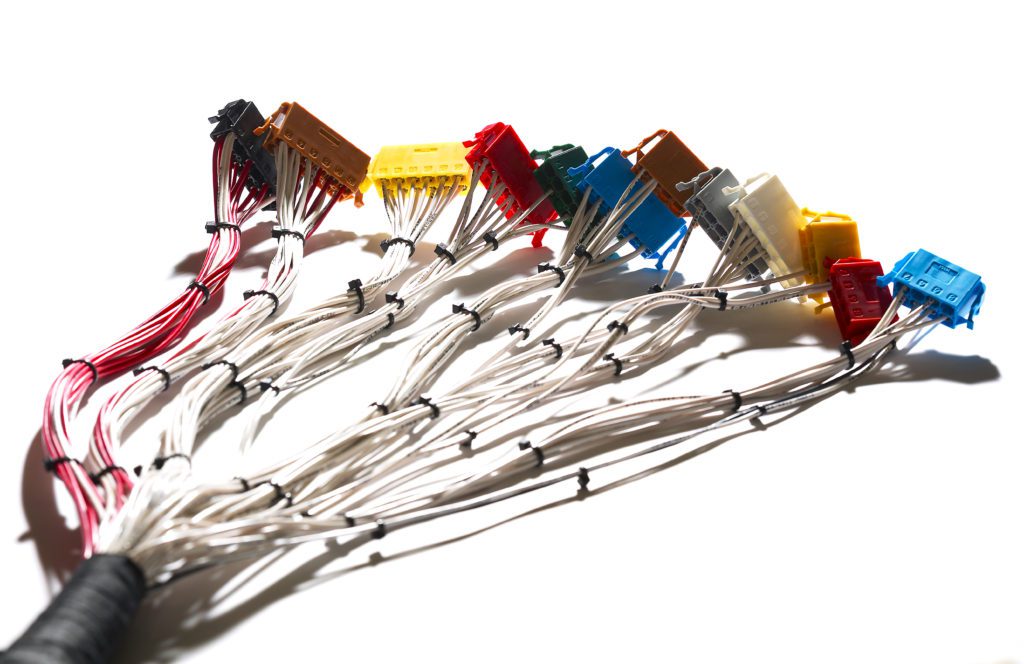

The E3.Harness flattening tool analyzes the 3D geometric data from MCAD systems to help designers automatically create a formboard manufacturing layout. The harness flattening process accepts supported inputs directly from MCAD applications through E3.3DRoutingBridge and E3.3DTransformer. The ability to automatically or manually select the harness backbone drives the formboard structure. The elimination of manual recreation of harness structure simplified the overall MCAD to ECAD process.

Electrical and Mechanical Collaboration

Automatic and manual harness backbone selection

Supports cable clips and protection

Automatic formboard creation

Automatic functions in E3.series help the user avoid errors such as automatic selection of mating connectors, connector pin terminals selected based on the wire gauge, and short-circuit prevention. Any wire or cable properties, such as color, cross-section, shielding, twisted-pair, length, insulation, stripping distance, additional lengths, material number, or tooling, can be fed into the production environment.

E3.3DRoutingBridge:

E3.3DTransformer

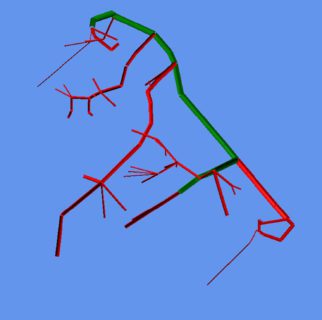

The 3D geometric data extracted from supported MCAD systems forms the input for the E3.Harness Flattening tool. The harness is then visualized in 3D to determine the most appropriate backbone. The diameter of the harness bundles drives the automatic selection of the harness backbone. Once the backbone selection is confirmed, the harness is flattened with all branches emitting from the backbone.

Once flattened, the harness data is then imported into E3.formboard. The import includes segment lengths, connections, wires, connectors, splices, protection, and clips. The connectors automatically associate with the logical schematics, and wires automatically route in the harness if the original schematic source was E3.series.

Enhanced functionality for designing cables and cable harnesses. Different views of the design enable the creation of specific documents for production, start-up, and service.

Creates build-to-print detailed 1:1 harness designs; linked dynamically to E3.cable drawings.

Supports the custom wire and cable harness market. The integrated module enables harness manufacturers to create accurate quotations and estimates, and full nail-board and peg-board documentation.

Transform 3D MCAD data into E/E topology model using native and industry-standard file formats. Eliminate errors with simple healing and fix functions for routing optimization.

A powerful interface between E3.series and leading 3D MCAD tools. Share schematic and connection information between ECAD and MCAD teams using standard data formats.

Start Your Test Drive Today