Around 10 years ago, Endress + Hauser standardized the engineering toolsets used across all operations. This provided the basis for important synergies through standardizing components, reusing designs, and developing modular products.

With PCB data and process management solutions from Zuken, Endress + Hauser has standardized development and manufacturing processes across five geographically-distributed operations, enabling company-wide parts standardization, design-reuse and increased engineering productivity.

Results

Right from the beginning, the perspective went beyond mere standardization of CAD software to achieving R&D benefits across divisions: “We were aware that a unified CAD environment alone would have provided only limited leverage for synergy effects. Since each operation was using a component database of its own, it was impossible to reuse existing designs across operations,” says Paul Burger, Group Leader PCB R&D.

All components used across all operations adhere to a unified material numbering system, and every material number is backed up by a choice of approved and certified second-source components so that the production can be maintained in cases of shortage.

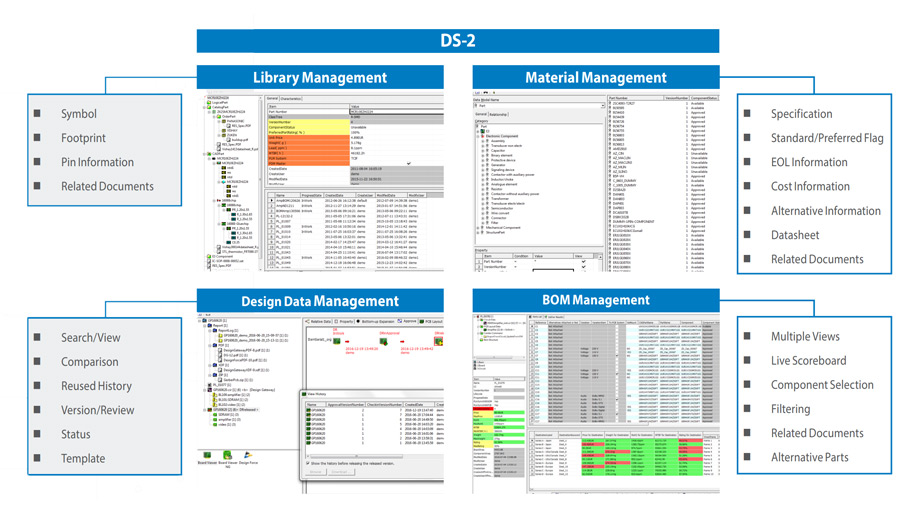

Today, all design data generated in the Endress+Hauser Group are managed and provided within DS-2. Each employee can directly retrieve all data they are authorized to access, from within their user profile. If a change is made, the system automatically creates a new revision, so there are comprehensive safeguards in place to ensure that data released for manufacturing are not compromised due to errors.

Related products

Discover more about the products that helped Endress+Hauser

- Products

Zuken’s engineering data management platform DS-CR has been created to support the specific demands of PCB design data management. It combines multi-site library, design data and configuration management into a unified engineering environment.

- Products

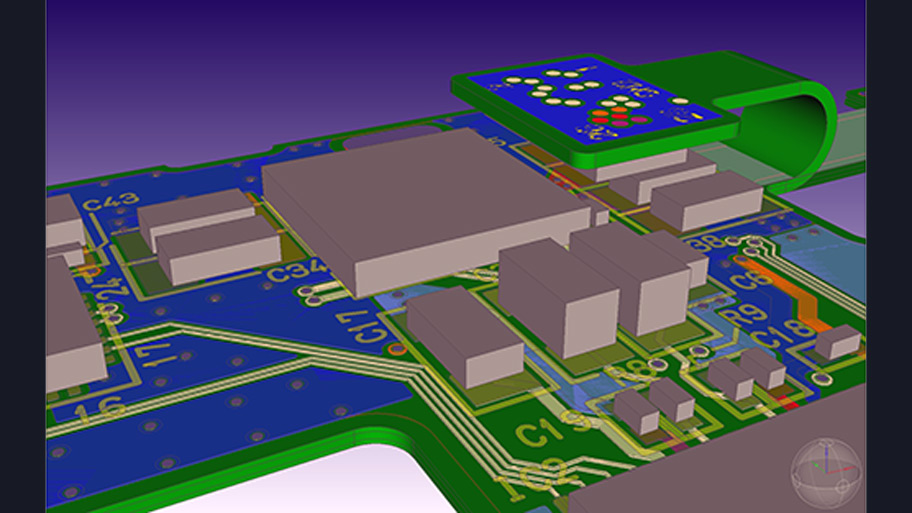

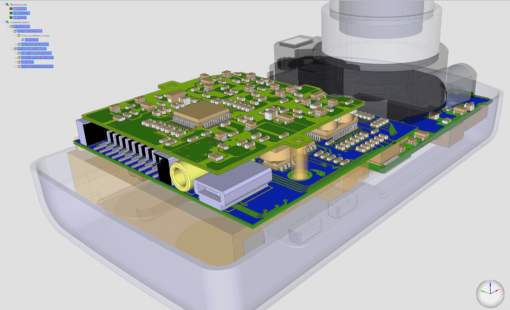

Design Force combines traditional 2D design with native 3D design and the latest human interface techniques, accelerated graphics and almost instantaneous rendering and refreshing. It is the fastest, most effective PCB design solution available today. Design Force enables design teams to layout their designs in the context of a complete system or product.

- Products

Building a competitive product today is much more difficult than a few years ago. Existing PCB-centric design processes are limited to a single PCB and do not provide the necessary tools for today’s competitive product development environment. PCB-centric design processes are falling behind.