WESTFORD, MA, USA and MUNICH, GERMANY, JULY 12, 2022 – Kawasaki Heavy Industries, Ltd. has introduced the E3.series electrical control and wire harness design system and the DS-E3 product data management system (PDM) from Zuken Inc. for the electrical design of aircraft for the Ministry of Defense of Japan. The software introduction aims to reduce the person-hours required to ensure traceability of wire harnesses by model number as required by aviation industry standards. A model number is a unique number assigned to an aircraft of the same model for identification purposes.

Because an aircraft is built to last for decades, strict quality control and traceability are essential throughout the lifecycle of the aircraft to ensure high standards of safety. As the aircraft bodies developed by Kawasaki Heavy Industries for the Ministry of Defense of Japan have an extremely long product lifecycle of 50 years, a considerable number of person-hours was required to understand model-specific design and manufacturing details and subsequent changes to equipment and wire harnesses across their maintenance lifecycle.

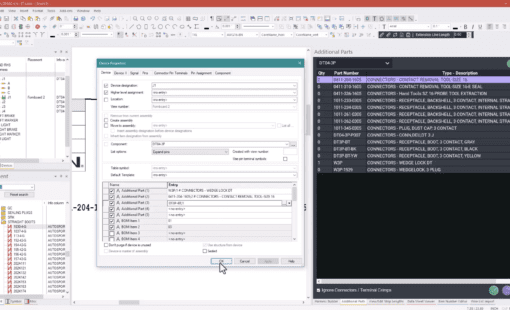

To address these issues, Kawasaki Heavy Industries introduced Zuken’s E3.series and DS-2 software suites, which are widely adopted in the aviation industry. The new procedure automates compliant management of design data and the release of drawings at each phase of the design and manufacturing processes, thereby reducing manual overhead and enabling traceability in the design and manufacturing of electrical wire harnesses. Overall, this new design and manufacturing procedure has significantly reduced the hours required to create data for the test of 40,000 aircraft wire harnesses, which previously required an effort of 12 person months.

Commenting on the benefits of Zuken’s E3.series and DS-2 software, Toshinori Kakui, Senior Staff in the Electrical Systems Engineering Department of Kawasaki Heavy Industries Aerospace Division, said, “Zuken’s E3.series and DS-2 software improved design operations have accelerated the delivery of drawings and shortened manufacturing lead times.”

About Kawasaki Heavy Industries

Together with about 100 group companies in Japan and overseas, Kawasaki Heavy Industries oversees the formation of a technology corporate group that spans a wide-ranging field from land, sea, air, and space. Building on a history that exceeds a century, the group covers a wide range of markets and technologies.

- Aerospace – aircraft, and satellites.

- Rolling stock – including Shinkansen and New York subway

- Ship and offshore structure – gas carriers, large tankers, submarines,

- Energy solutions – energy equipment and management systems.

- High-level engineering technologies – environmental and recycling plants, industrial plants, precision machinery, industrial robots, and infrastructure equipment.

- Leisure and power products – motorcycles, off-road four-wheelers, “Jet Ski®” watercraft, etc.

For more information about the Kawasaki Heavy Industries Group and division, visit https://global.kawasaki.com/en/

Related Resources

- Success Stories

- Products

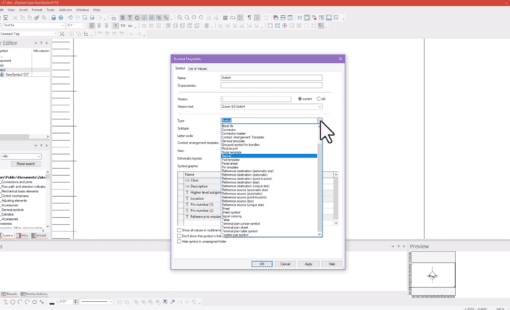

E3.series is a Windows-based, scalable, easy-to-learn system for the design of wiring and control systems, hydraulics and pneumatics. The out-of-the-box solution includes schematic (for circuit and fluid diagrams), cable (for advanced electrical and fluid design), panel (for cabinet and panel layout), and formboard (for 1:1 wiring harness manufacturing drawings). Integrated with MCAD, E3.series is a complete design engineering solution from concept through physical realization and manufacturing output.

- Press Release

- Press Release