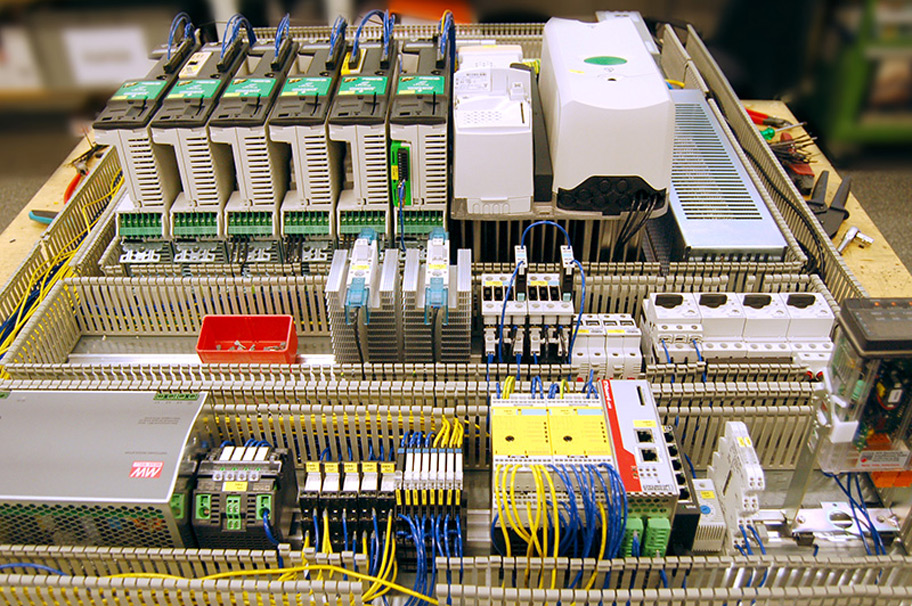

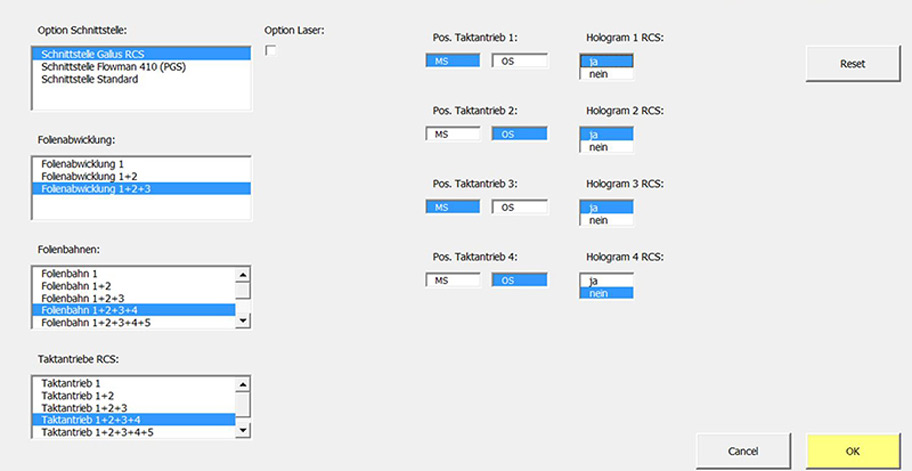

E3.series provides the functionality to customise the electrical wiring for a specific machine out of a selection of valid options for the ‘reference machine’ that was developed. “E3.series delivers the exact 1:1 wiring for the machine as ordered by the customer. And as E3.series is fully integrated with our ERP system, when the wiring information is generated it’s the trigger for a host of other assembly-related information. The order placement to machine delivery time has been cut from up to 17 weeks to as fast as 10 weeks.”

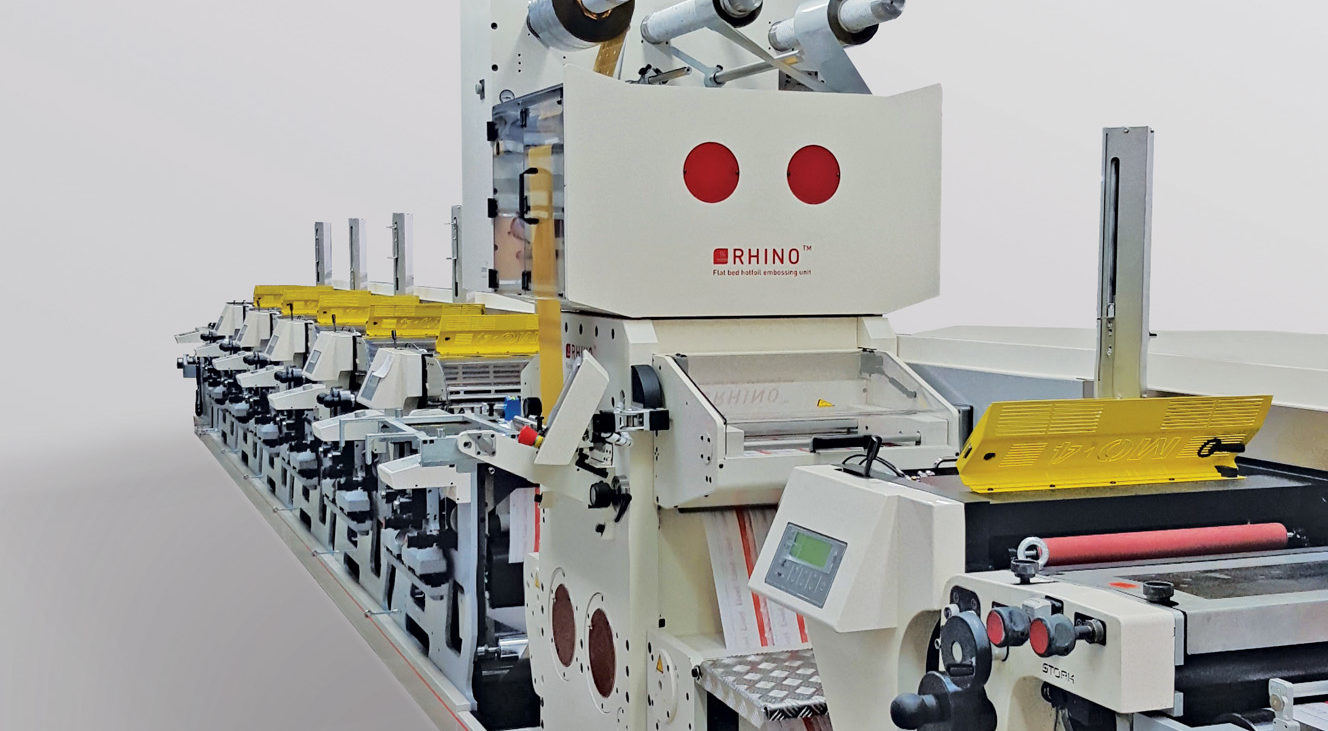

When Pantec Automation’s customers faced pressure from low-cost counterfeit machinery, they realised the best way to fight back was to help customers reduce their own costs. Through wholesale efficiency improvements achieved by expanding its use of Zuken’s E3.series and integrating it into its ERP/PPS, Pantec Automation enabled its customers to better serve end-users.

As well as meeting cost-reduction goals, the company reduced the time from order placement to delivery of the fully assembled electrical equipment from an average of 15 to eight weeks – a massive cut of around 50%.

Results

“Our machine builders can now provide their customers with quotations within a matter of days.” Until recently, the development and build of a machine for a plant used to be an engineering (design) intensive and time-consuming task for both the machine builder and Pantec Automation. For instance, when liaising with a customer the machine builder’s salespeople were, and continue to be, learning about the customer’s requirements. They then needed to consult with engineers in their offices to determine if and how the exact requirements could be met. Once the requirements were established, Pantec Automation would then quote for the provision of the control cabinets, HMIs and cabling; which would need to be done before the machine builder could provide its customer with a quotation.

Machine complexity, or rather machine uniqueness, presents a challenge at the best of times – but Pantec Automation’s customers are facing another more pressing problem. “Many of our customers’ markets are now being served with lower-cost and lower-quality foreign imports, which was always a danger because some of the countries they sell to, where manual labour is very cheap, also have a reputation for copying.” The best way to minimise the risk of copying is to make the machines cost less. Machine builders can also become more competitive by reducing their delivery times. Pantec achieved this using E3.series – mainly due to productivity gains by using modular design.

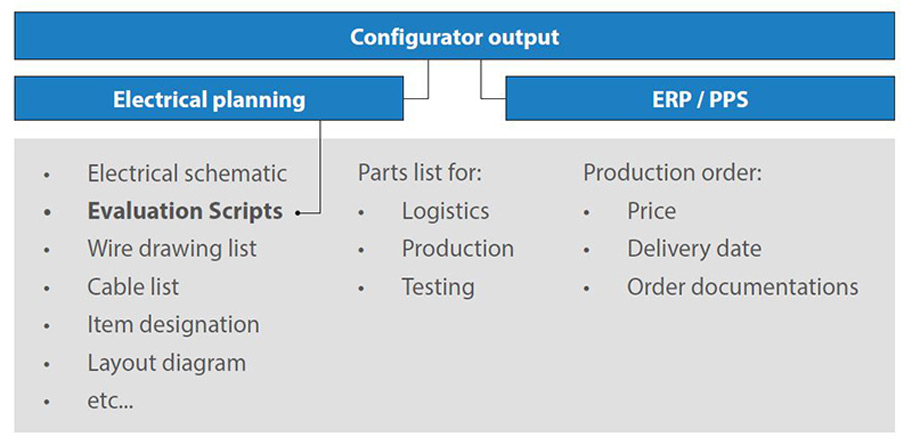

Through tighter integration within Pantec Automation’s IT system, E3.series began playing a crucial role within a ‘Configurator’ tool the company built for its customers (the machine builders) to use when talking to their customers. The Configurator presents a list of valid variants and options. “It required engineering knowledge to understand which parts of a machine could work with other parts.There might be coupe and convertible model variants, but in terms of options a sunroof would only be available on the coupe.” E3.series had this logic built-in.

“Industry is crying out for modularity. We’ve empowered our customers to offer modular solutions which can be customised much faster and can be manufactured for a lower cost than before. We still build and deliver control cabinets, HMIs and cables but, for the first time, E3.series is enabling us and our customers to treat them as modular elements and options. Also, a few of our customers now carry some of our units as stock items that just require configuration in software before going into service. That’s a game-changer.”

Related products

Discover more about the products that helped Pantec Automation