Zuken believes that one of the secrets to success under Industry 4.0 is making better use of data. It is possible to having seamless exchanges of data between all essential engineering design tools and PLM, ERP and PDM using Zuken’s DS-2 engineering data management platform.

Helping to respond to the challenges of digitization

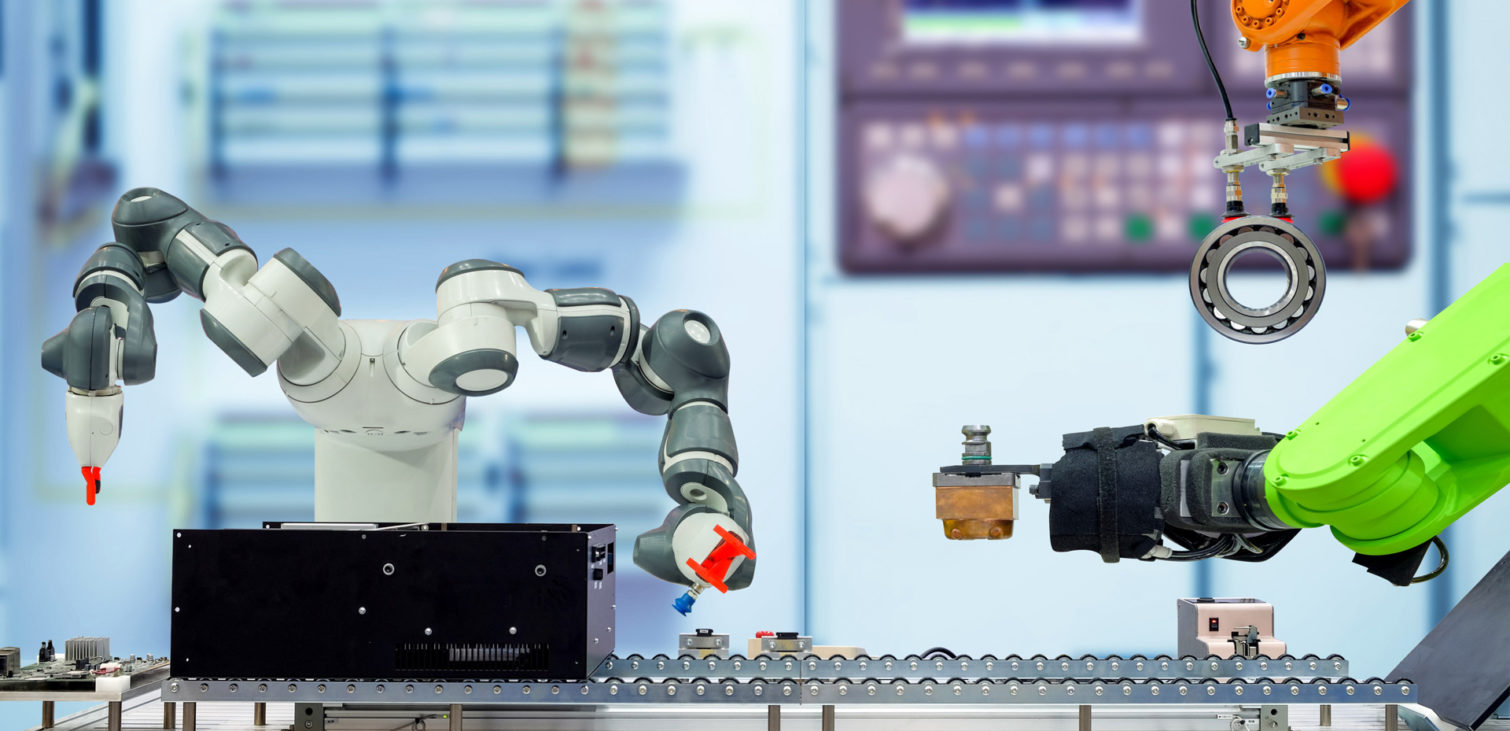

Networked production processes driven by cutting-edge information technology are becoming a reality in the era of Industry 4.0. With a continuous information exchange between materials, inventory, machinery and control equipment through the Internet of Things (IoT), Industry 4.0 promises increased productivity, better reaction to market opportunities and, consequently, competitive edge and profitability.

We are helping customers respond to the challenges around digital engineering for Industry 4.0 and the Internet of Things. The backbone of our offering is our engineering data management platform, DS-2, for electrical and electronic engineering, which offers fully native or “domain” data management. This is complemented by database-driven authoring tools that automatically transport comprehensive details of electrical and electronic equipment down to a component and connection level.

Our expertise

By linking ECAD, MCAD and ERP into an integrated digital engineering and sourcing process, customers have achieved sizable benefits for both sourcing and service. One of the most advanced examples is KRONE, a major agricultural machinery manufacturer, who made solid progress in achieving its Industry 4.0 goals by implementing an interdisciplinary product development process using Zuken’s E3.series. The success story can be found below under “related resources”.

Maintaining and upgrading plant and equipment can be made easier by better use of engineering design data. For this to succeed, all stakeholders need access to the most relevant view of live data for their activities.

Industry 4.0 accommodates automated configure-to-order (CTO) within manufacturing scenarios, which gives companies the ability to define customer-specific functionality in a controlled process. This, in turn, ramps up variety-induced complexity. Companies that do well will be those that set out not to reduce complexity, but rather to find the optimum tools and processes with which to embrace it – especially for engineering data management.

Related resources

Check our latest webinars, white papers, blog posts and more

- On-Demand Webinar

- On-Demand Webinar

- White Paper

- Press Release