Printed electronics manufacturers use Zuken’s CR-8000 Design Force DfM Centre and DfM for Inkjet software to automate the process of applying rules for different board technologies, including flex, to improve design quality and manufacturing yields. Design Force is the only design tool that allows specification of unique rules for materials, meaning no extra steps are needed when 3D printing to silver and any other future conductive materials.

Working with industry leaders to enable new applications

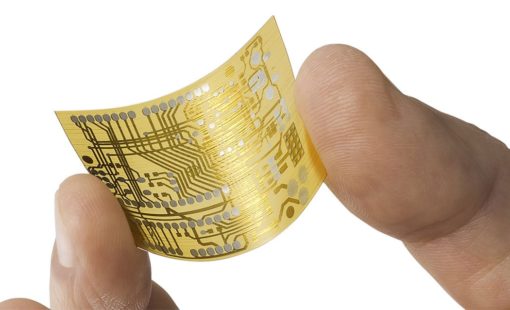

Printed electronics is not just one of the most exciting and fastest growing areas of additive manufacturing technology, but it can also be seen as one of the most democratic in term of cost and access. It is enabling new applications in areas such as wearables, medical and RFID tagging for IoT, as well as having a transformational effect on electronics design for manufacture (DfM) by enabling rapid prototyping, speedier proof-of-concept circuits, up-front design validation, and Agile hardware development.

-

Automating design rules

-

Printed electronics manufacturers use Zuken’s CR-8000 Design Force DfM Centre and DfM for Inkjet software to automate the process of applying rules for different board technologies, including flex, to improve design quality and manufacturing yields. Design Force is the only design tool that allows specification of unique rules for materials, meaning no extra steps are needed when 3D printing to silver and any other future conductive materials.

-

Seamless design to 3D printing

-

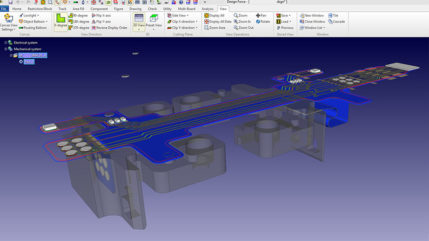

Zuken and Nano Dimension, a leader in electronic printing technologies, are working together to give 3D printer users a seamless experience from design to output and optimization, and to reduce prototype turnaround times. Nano Dimension’s DragonFly 2020 3D printer for multilayer printed circuit boards offers simultaneous design of components made of different materials, and via a SOLIDWORKS add-in, enables design and print of complex, non-planar structures.

-

Developing standards for non-planar objects

-

Zuken is helping develop IEC standards for 3D formatting and printing of non-planar objects, and through our partnership with Nano Dimension we are helping define IPC standards in this area.

Our expertise

Zuken and Nano Dimension, a leader in electronic printing technologies, are working together to give 3D printer users a seamless experience from design to output and optimization, and to reduce prototype turnaround times. Nano Dimension’s DragonFly 2020 3D printer for multilayer printed circuit boards offers simultaneous design of components made of different materials, and via a SOLIDWORKS add-in, enables design and print of complex, non-planar structures.

Zuken is helping develop IEC standards for 3D formatting and printing of non-planar objects, and through our partnership with Nano Dimension we are helping define IPC standards in this area.

Related resources

Check our latest webinars, white papers, blog posts and more

Related products

- Products

Building a competitive product today is much more difficult than a few years ago. Existing PCB-centric design processes are limited to a single PCB and do not provide the necessary tools for today’s competitive product development environment. PCB-centric design processes are falling behind.

- Products

PCB Design for Manufacturing (DFM) enables designers to handle the increasing complexity and diversity of today’s PCBs, while ensuring high final product quality, and accurate outputs for the manufacturing processes. With a robust set of features for data preparation and embedded verification to ensure manufacturing specifications are met...